Wheel conveyor – Optimal Solution for Transporting Goods in the Factory

In the context of factories increasingly moving towards automation and optimizing operations, Wheel Conveyor becomes a flexible, economical and effective transportation solution. Not only does it help move light goods easily, this type of conveyor is also diverse in materials and structure, suitable for many different production models. The following article will help you better understand the concept, structure, advantages, applications and classification of Wheel Conveyor to choose the right one for your factory.

What is a Wheel Conveyor?

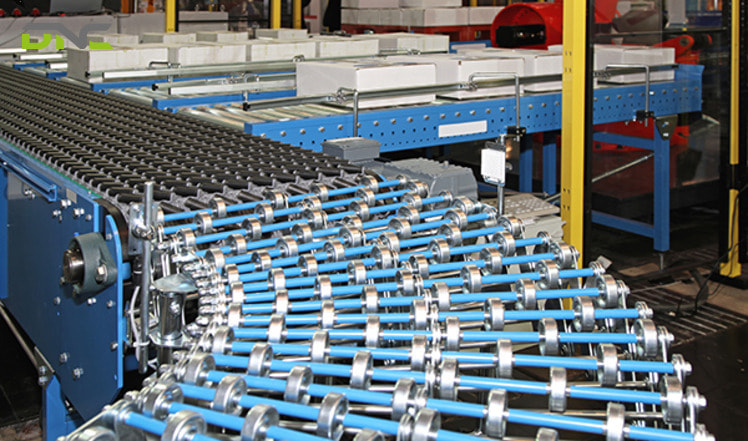

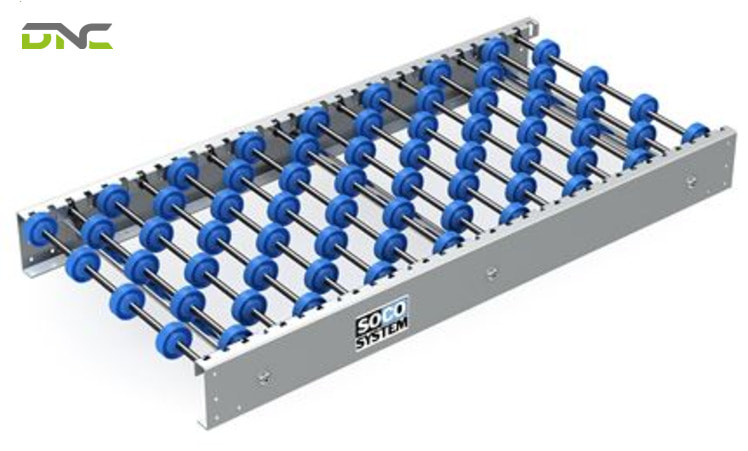

Wheel Conveyor is a type of conveyor that uses small wheels mounted in parallel on a metal frame to form a surface for transporting goods.

This system operates by gravity or manual push, allowing objects to move easily without the need for motors or complex transmission systems.

This type of conveyor is often used to transport flat-bottomed packages such as cartons, plastic trays, paper boxes… in manufacturing and warehouse environments.

How many parts does a Wheel Conveyor consist of?

A Wheel Conveyor has a fairly simple structure but is optimized for transporting light to medium-sized goods in an industrial environment. Below are the 4 main parts that make up this system:

Conveyor frame

- This is the main structural part that supports the entire system.

- Usually made of galvanized steel, stainless steel or aluminum profiles, ensuring rigidity and load-bearing capacity.

- The design can be fixed or foldable/open, suitable for flexible working spaces.

Wheels

- This is the part that comes into direct contact with the goods.

- Usually made of hard plastic, metal or rubber, depending on the type of goods and conditions of use.

- The wheels have a smooth rotating shaft to help the goods move smoothly with little friction.

- The distance between the wheels can be adjusted to suit the size of the package.

Wheel and support shaft

- The wheels are fixed on the metal shaft, mounted on the horizontal support bar on the frame.

- This shaft system is designed to withstand high forces and rotate flexibly, helping the wheels operate stably.

Legs/Stand

- The legs can be fixed or height adjustable, suitable for the terrain and height of the chain.

- Many types also integrate locking moving wheels, supporting easy movement of the conveyor.

Wheel Conveyor has 4 main parts: Conveyor frame, Wheels, Wheel and support shaft, Legs/Stand

How many types of Wheel Conveyor are there?

Wheel Conveyors can be classified according to many different criteria such as wheel material, conveyor frame structure and transport direction. Understanding each type will help businesses choose the right solution suitable for production characteristics, layout space and investment budget.

Classification by wheel material

- Plastic wheels are usually made from hard plastics such as PVC, PP or nylon. The outstanding advantages of this type of wheel are light weight, low cost and the ability to move goods smoothly thanks to low friction. However, they are susceptible to wear and are not suitable for transporting products with large loads.

- Metal wheels are usually made from stainless steel, stainless steel or galvanized steel. They are durable, have good load-bearing capacity and operate stably in heavy industrial environments or high temperatures. However, metal wheels often make a lot of noise when operating and are quite heavy.

- Rubber wheels are a combination of a metal or plastic core and an outer rubber layer. The advantages of this type of wheel are the ability to absorb shock, reduce noise and limit damage to fragile products. However, rubber wheels cannot withstand large loads and are easily affected in oily environments.

Classification by structure

- The fixed type Wheel Conveyor is designed to be installed at a fixed position in the production line. With a sturdy structure, this type ensures high stability during operation, suitable for areas with fixed arrangements such as product inspection or packaging areas.

- The mobile type Wheel Conveyor is more flexible with an integrated wheel design under the frame, allowing users to easily move and change the location of use. This type is very convenient in warehouses, import and export areas or semi-automatic lines.

- The foldable type Wheel Conveyor (flexible) is designed as a flexible folding system, which can be extended, retracted or bent depending on the usage needs. Thanks to its high mobility, this type helps save space and is easy to move to many different areas.

Classification by transport direction

- The straight type Wheel Conveyor is the most popular type, helping to transport goods in a fixed straight line from one point to another.

- The curved Wheel Conveyor has a curved structure with angles such as 45°, 90° or customized according to the factory space. This design helps to flexibly connect between different areas, especially useful in factories with U-shaped, L-shaped layouts or need to guide around wall corners.

- The inclined Wheel Conveyor uses gravity to move goods from high to low positions, usually without the need to use a motor, thus saving operating costs.l

Depending on each industry, product volume, factory space and level of automation, businesses can flexibly choose or combine Wheel Conveyor types to achieve optimal operating efficiency.

How many types of Wheel Conveyor are there?

Why should businesses use Wheel Conveyor in automated production lines?

Wheel Conveyor is not only popular because of its simple structure but also because of a series of outstanding advantages in practical application in factories and warehouses. Below are the reasons why this type of conveyor is increasingly popular in automation systems:

- Increase production productivity: When applying Wheel Conveyor to the production line, workers do not need to carry goods manually, instead they just need to push lightly so that the goods slide along the conveyor belt. This not only reduces the risk of occupational injuries, but also helps increase order processing speed, improving the overall efficiency of the entire system.

- Low investment cost: Unlike other types of conveyor belts that use motors or complex control systems, Wheel Conveyor does not need electricity or motors, helping to significantly save initial investment costs.

- Energy saving: With the principle of operating by gravity or manual pushing, Wheel Conveyor helps businesses completely eliminate electricity costs for transportation in the production line.

- Easy to install: Wheel Conveyor has a compact and modular design, easy to install, remove or adjust the length according to usage needs. Some models also have a foldable design (flexible wheel conveyor), which can be extended, shortened or bent.

- Simple maintenance, high durability: When there is damage, businesses only need to replace individual wheels or axles without affecting the entire system. This helps save time and maintenance costs significantly.

Benefits of Wheel conveyor

What is the application of Wheel Conveyor in production?

In the context of factories constantly transforming digitally and moving towards automation, Wheel Conveyor becomes one of the simple but effective transportation solutions, helping to increase productivity and reduce operating costs.

- Goods transfer station between production stages: Wheel Conveyor is often used to transfer boxes, components, semi-finished products between stages in the production line.

- Application in packaging and sorting areas: In the packaging area, Wheel Conveyor helps transport finished boxes, packages or light pallets to locations for labeling, quality inspection, packing or sealing.

- Import – export area: In the warehouse or import and export area, Wheel Conveyor is used to extend from containers, trucks into the warehouse, helping to move packages quickly without using forklifts or too much human effort.

- Light manufacturing and consumer packaging industry: With the advantage of being suitable for flat-bottomed goods, uniform size and light to medium weight, Wheel Conveyor is very popular in industries such as: Food & beverage, FMCG, Electronics – components.

What is the application of Wheel Conveyor in production?

Where to buy reputable automatic wheel conveyor lines?

If you are uncertain about where to purchase a wheel conveyor, DNC Automation is an excellent option for you. Many customers have trusted DNC to provide automation solutions in the production process and have had positive experiences because:

- DNC is a leading technology, automation, and engineering company in Malaysia with over 15 years of experience in the field of automation

- System integration machinery, Internet of Things (IoT), Industry 4.0, and WinCC Scada System

- Diverse designs and sizes are suitable for many domestic and foreign houses. The equipment is 100% genuine and imported from Malaysia.

Please contact us via the hotline below if you have any questions about the product, we are happy to answer you!

- 0 views

- 0 Comment

Recent Comments