Vertical Conveyor – The No. 1 Solution to Optimize Your Production Process

Vertical conveyor systems help businesses optimize production productivity and bring outstanding efficiency thanks to modern technology. With a load capacity of up to 6 tons, operating continuously 24/7, the device can be considered a powerful assistant in the production process of all industries.

So do you want to find out why this line is one of the most worth-investing automatic lines for your business? Let’s explore with DNC the application, classification, advantages, as well as reputable conveyor suppliers.

What is a vertical conveyor?

Vertical conveyor systems are specialized mechanical devices for transporting goods, materials, components, etc. to high places. This device can reach heights of up to 120 feet, helping optimize time and increase business production capacity.

Conveyors have the principle of vertical reciprocating motion (VRC). VCR is a safer and more efficient alternative to elevators and transporting goods from basements to other floors. This method is more economical than other lifting solutions.

Introduction to vertical conveyor

What are the most common types of vertical conveyors?

Vertical conveyors are used in many fields and are divided into many types to meet specific requirements. The following are 4 main classifications: Continuous vertical conveyors (CVC), Vertical reciprocating conveyors (VRC), Dual lane spiral, and Circulating vertical conveyors.

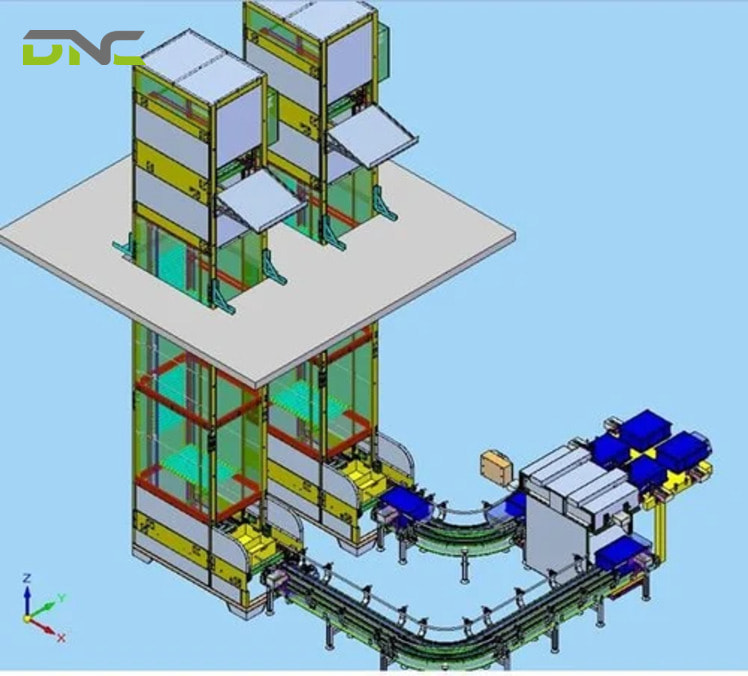

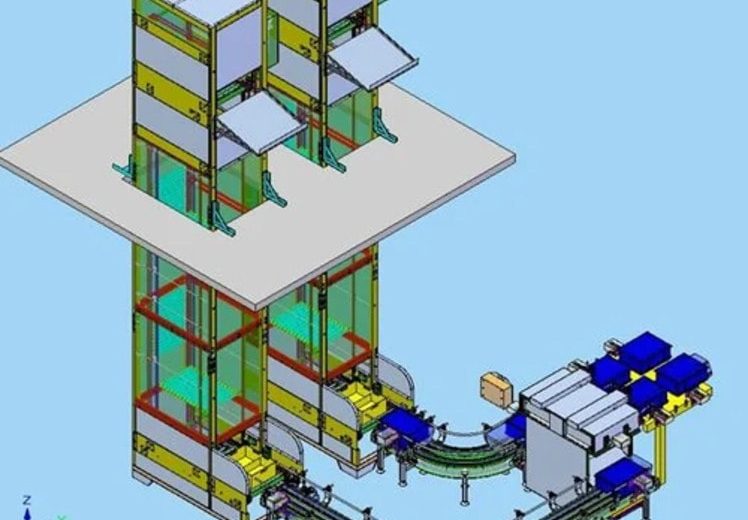

- Continuous vertical conveyors (CVC) are designed to transport products with high capacity between floors. The equipment is often suitable for products such as cardboard boxes, wheels, boxes, etc.

Continuous vertical conveyors (CVC)

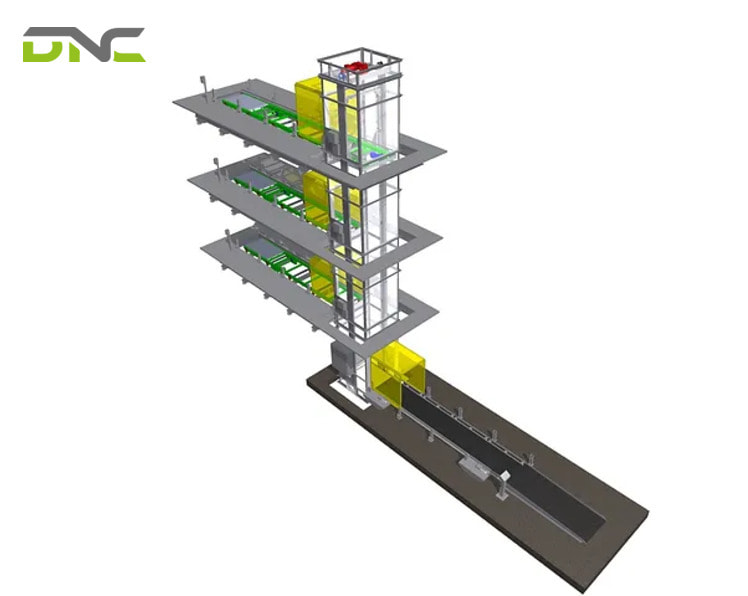

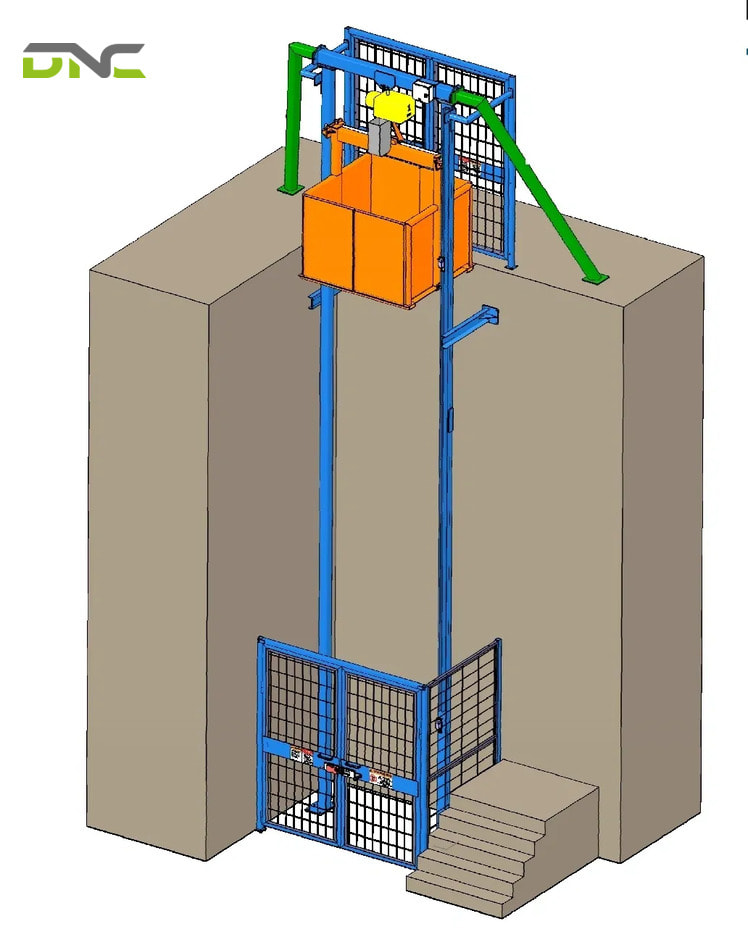

- Vertical reciprocating conveyors (VRC) have a vertical operating principle like an elevator. The equipment is covered with a protective cage to ensure the materials’ safety. They are designed to be used at many different heights and are often used in construction sites or high-rise buildings.

Vertical reciprocating conveyors (VRC)

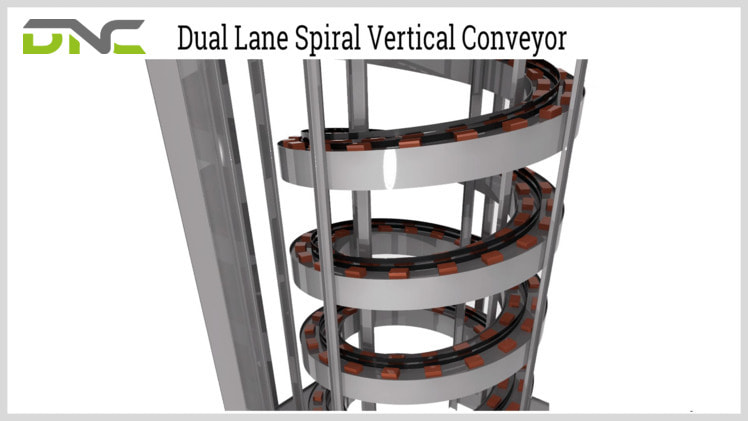

- Dual lane spiral: This design has twice the capacity of a single-lane vertical conveyor, allowing goods to be moved up and down. This conveyor helps businesses save time and increase productivity.

Dual lane spiral vertical conveyor

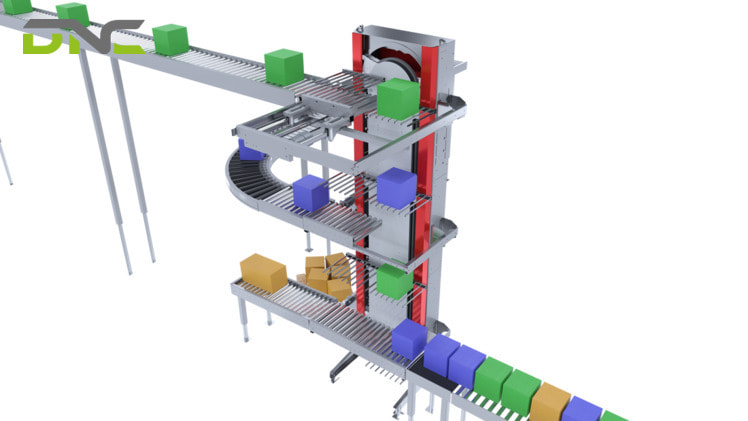

- Circulating vertical conveyors are similar in design to continuous vertical conveyors, but they differ in how they handle material. The platforms of recirculating vertical conveyors are supported by blockchains that complete the conveyor circuit. These chains help keep the platforms balanced and ensure smooth operation, preventing products from falling out of the container.

Circulating vertical conveyors

Why should you choose a vertical conveyor to transport goods?

Do you wonder why vertical conveyors are one of the important and commonly used systems in manufacturing plants? Here are some of the outstanding benefits that vertical conveyor systems bring to businesses:

- Vertical conveyor systems allow businesses to make the most of vertical space, especially in factories or warehouses with limited areas. This helps reduce construction and warehouse rental costs

- Easily transport heavy goods of all shapes and sizes

- Fully automated systems help increase labor productivity, saving costs for businesses

- Capacity to withstand heavy objects up to 6 tons.

- Limit work accidents when having to transport heavy goods for a long time.

- Vertical conveyor systems are integrated with management software such as ERP or WMS, allowing businesses to monitor production processes and manage warehouses remotely.

Benefits of vertical conveyor for business

Which industries can benefit from the use of vertical conveyors?

Vertical integration is a cross-industry requirement. Here is how different sectors apply it:

- Food & Beverage (F&B): Used to move crates of produce or bottled drinks from the processing floor to high-level sterilization or packaging zones.

- E-commerce & Logistics: Crucial for multi-tier fulfillment centers where parcels need to move from picking mezzanines to ground-floor shipping docks.

- Pharmaceuticals: Ideal for cleanroom environments where vertical lifts can be enclosed to prevent contamination while moving sensitive medical supplies.

Automotive Manufacturing: Employed to move heavy sub-assemblies or engines between different stages of the assembly line located on different levels.

Applications of vertical conveyors in industries

How much does a vertical conveyor cost?

The price of automatic vertical conveyor lines on the market usually fluctuates between $10,000 – $15,000. However, this price can still change depending on several factors such as:

- Brand: Each brand may have different prices, depending on pricing policies, operating costs, and accompanying services.

- Height and load capacity: The higher the conveyor belt or the higher the load capacity, the more expensive it will be than the lower type.

- Classification: Each type of vertical conveyor also has different prices due to various operating methods and production technology.

To know the exact price of vertical conveyor lines at present, you should contact the suppliers directly for advice and specific quotes.

Price of vertical conveyor

What technical specifications should you consider when designing a system?

When consulting with an automation partner like DNC Automation, you must define the following parameters:

- Payload Capacity: The maximum weight per unit and the cumulative weight the system must support at any given time.

- Throughput Requirements: Measured in “Parts Per Minute” (PPM) or “Cycles Per Hour.” This determines if you need a Continuous or Reciprocating model.

- Product Dimensions: The footprint (Length x Width) and the height of the largest and smallest items. This dictates the size of the carriers and the width of the lift shaft.

- In-feed/Out-feed Orientation: Does the product enter from the front and exit the back (C-flow) or exit from the side (Z-flow)?

- Environmental Factors: Considerations for wash-down environments (stainless steel construction), explosive atmospheres (ATEX rating), or cold storage.

Where to buy reputable automatic vertical conveyor lines?

If you are uncertain about where to purchase vertical conveyor belts, DNC Automation is an excellent option for you. Many customers have trusted DNC to provide automation solutions in the production process and have had positive experiences because:

Investing in a vertical conveyor system is a long-term commitment that impacts your entire production flow. At DNC Automation, we don’t just provide equipment; we deliver a fully integrated solution backed by a decade of engineering expertise. Here is why leading enterprises choose us for their vertical material handling needs:

- Customized Engineering & Strategic Consultation

- Seamless “Plug-and-Play” System Integration

- Uncompromising Focus on Safety and Compliance

- Comprehensive Lifecycle Support and Maintenance

- Proven Track Record in Diverse Industries

- 41 views

- 0 Comment

Recent Comments