How do tubular drag conveyors improve efficiency in bulk material handling?

Tubular drag conveyors not only help businesses optimize production productivity but also bring outstanding efficiency thanks to modern technology. With a maximum conveying speed of 2,000 cubic feet/hour and the ability to operate continuously 24/7, the device can be considered a powerful assistant in the production process of the business.

So do you want to find out why this line is one of the most worth-investing automatic conveyors for your business? Let’s explore the detailed structure, advantages and things to note when buying this conveyor with DNC.

What are tubular drag conveyors?

A tube conveyor is a mechanical system that works by moving bulk materials through a closed-space tube. This tube can be made of steel, glass, or plastic depending on the type of product the business is producing.

This type of conveyor is a great solution for moving bulk materials such as powders, granules, dry goods, or other fragile/friable food products.

Definition of tubular drag conveyor

How is a tubular conveyor constructed?

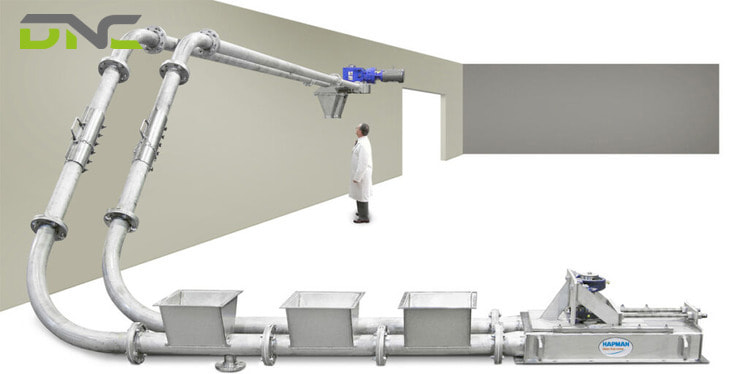

Structure of tubular drag conveyor

The tubular drag conveyor has a simple configuration consisting of 5 parts: drive unit, funnel, inspection section, compression coupler, and controller.

- Drive Unit: The Drive Unit in a tubular drag conveyor serves a critical role in powering and controlling the movement of the conveyor system.

Drive unit part in tubular drag conveyor

- Funnel: This part plays an important role in leading raw materials into the closed pipeline. The hopper is designed with many different sizes and connection heads, so it is suitable for a variety of business needs.

Funnel part in tubular drag conveyor

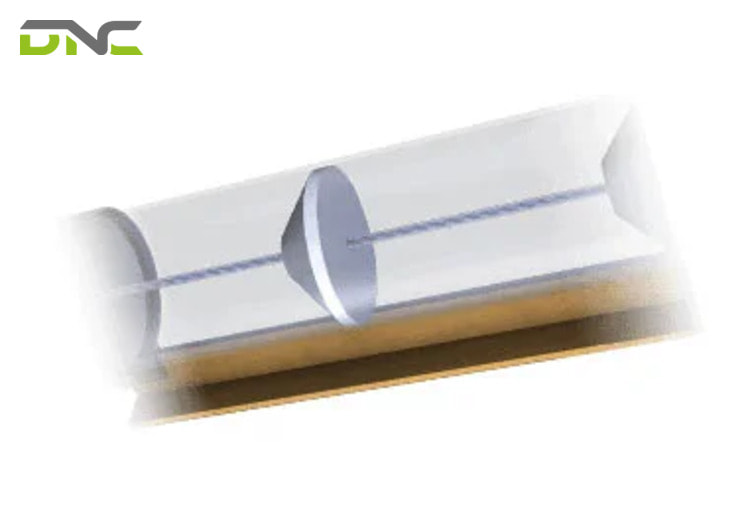

- Inspection Section: This section is made of steel, plastic, or transparent glass, allowing you to observe the product as well as monitor the production process. This part can be installed vertically or horizontally depending on your needs.

Inspection section in tubular drag conveyor

- Compression Coupler: This part facilitates the connection of pipes while ensuring a tight seal against air, water, or dirt.

Compression coupler in tubular drag conveyor

- Controller: The automatic controller combined with a PLC touch screen makes it easy to monitor the operation process.

In which industries are tubular conveyors commonly used?

The tubular conveyor is a device that is widely used in a variety of different industrial fields such as:

- Pharmaceutical Industry: Tubular conveyors are used to transport powders and granules to produce medicines. This production process is strictly controlled according to the regulations of the Ministry of Health.

- Food Processing Industry: Tubular conveyors are used to transport ingredients such as powders, spices, seeds,… The equipment is installed between other processing machines to transfer the product to the next step easily.

- Agricultural Industry: Conveyors are used to transport grains, animal feed,…

In addition, tubular conveyors are also used in fields such as chemicals, plastic manufacturing, etc. All are used to transport raw materials to the next stages.

Why should use a tubular drag conveyor line?

- It is ensuring product safety even when the product is fragile.

- Saves more than 50% energy compared to other conveyor systems

- Can be transported horizontally and vertically, thus meeting all customer needs

- The conveyor is made of high-strength stainless steel

- Easy to clean thanks to specially designed openings

- Increases production capacity with a maximum conveying speed of 2,000 cubic feet per hour

- The ability to operate continuously 24/7

Benefits of tubular drag conveyor

How much does a tubular drag conveyor cost?

Is a tubular drag conveyor expensive or cheap? This is one of the most common questions for buyers today. It can be said that this conveyor system has a more affordable price compared to other types of conveyor systems.

However, the price of a conveyor line depends on various factors such as operating capacity, technology, and machine brand… Typically, the price of a tubular drag conveyor ranges from $10,000 to $15,000, depending on the production needs of the business.”

Where to find reputable tubular drag conveyor solutions?

- DNC is a leading technology, automation, and engineering company in Malaysia with over 15 years of experience in the field of automation

- System integration machinery, Internet of Things (IoT), Industry 4.0, and WinCC Scada System

- Diverse designs and sizes are suitable for many domestic and foreign houses. The equipment is 100% genuine and imported from Malaysia.

- Professional consulting team, dedicated consulting for customers 24/7

- Prestigious warranty policy, professional after-sales service

- Robot solutions and automatic guided vehicles (AGV)

So, if you are looking for an automatic thermoforming packaging machine production line with a highly specialized team, please visit our official website. DNC Automation is committed to bringing you the best experience.

- 4 views

- 0 Comment

Recent Comments