Spiral conveyor belt best price 2024

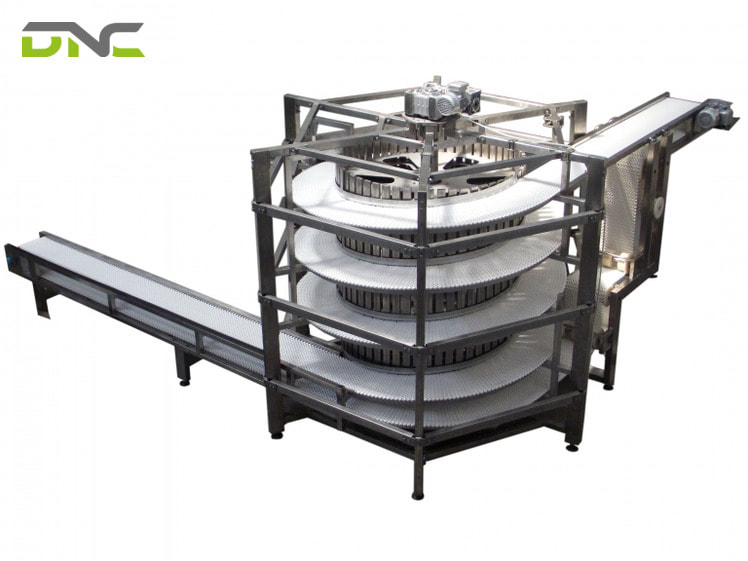

The spiral conveyor is a specialized machine in many production facilities that helps move goods automatically over long distances. The device has a vertical spiral structure, is compact and extremely suitable for many production facilities with limited space.

What is the spiral conveyor?

Compared to the efficiency that the spiral conveyor brings, the initial investment cost is completely worth it. The device has used many advanced technologies such as spiral accumulation, continuous spiral chain, and two-lane spiral technology… to create a very smooth, uninterrupted operating process and become the ideal device for many warehouses.

How much does it cost to install a spiral conveyor?

It is difficult to give a general price for a conveyor system. The price of this system depends on many factors such as the size, design, operating capacity and function of the machine.

However, the current market for conveyor solutions ranges from $7,000 to $20,000.

More expensive solutions tend to consume less energy, save time and provide efficient work performance.

How does the spiral conveyor work?

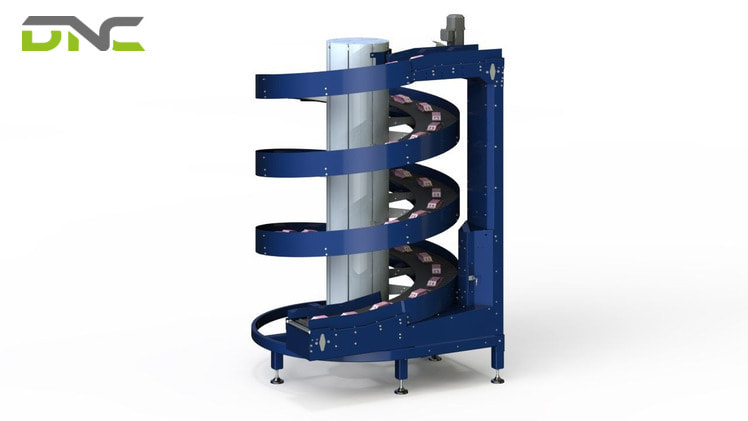

Spiral conveyor consists of spiral modules connected together by connecting rods and rotating shafts. The equipment operates on the spiral principle when the modules rotate in a counterclockwise direction, the product will be lifted and lowered automatically, eliminating the need for long linear conveyors, saving space and optimizing the production process.

How does the spiral conveyor work?

What technology is applied in spiral conveyors?

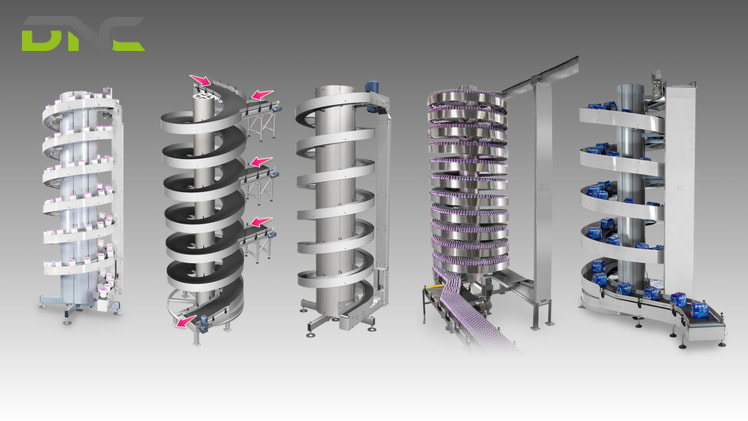

Spiral conveyors are designed to integrate many modern technologies that can solve many warehouse requirements such as spiral accumulation technology, continuous spiral chain technology, two-lane spiral technology, and Helix spiral technology…

Technology applied in spiral conveyor

- Spiral accumulation technology: is applied to divide accumulation areas into separate and independently controlled areas. This technology allows for more buffer time for product movement and is also a technology that helps optimize floor space effectively.

- Continuous spiral chain technology: This type of technology sounds simple but is an extremely powerful machine. They are controlled and monitored through a drive, when fully connected to the power source, the device is brought to a certain location, and the device will begin to operate cyclically and continuously.

- Two-lane spiral technology: helps save money and warehouse space, in some production facilities, many runways are needed to go up and down, so this technology is one of the best options.

- Helix spiral technology: similar to continuous chain spiral technology, will include 90 or 181-degree conveyor sections connected, at each section there will be different sensor and monitoring systems, ensuring safe distance during movement.

What are the advantages and disadvantages of spiral conveyors?

The advantages and disadvantages of spiral conveyors

Advantages

Spiral conveyors have become the optimal solution for production warehouses thanks to their outstanding advantages such as:

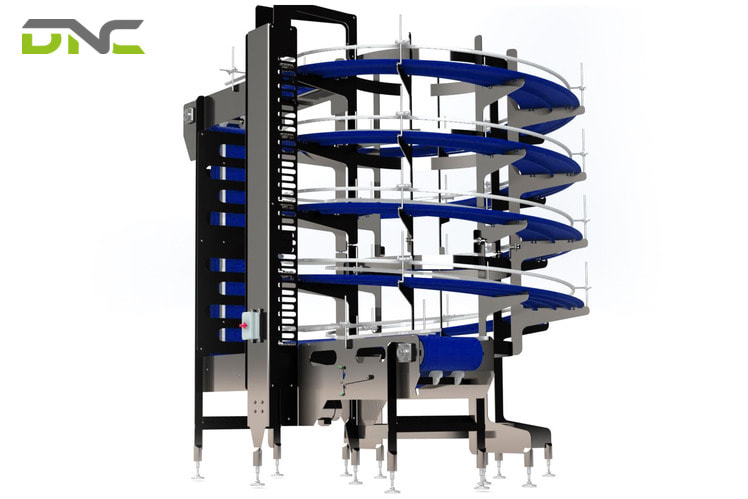

- Flexible design: the equipment has a unique vertical interface, sturdy structure, and high precision. Therefore, the conveyor can withstand large volumes of goods on the same runway.

- Overlapping slats: connecting and stacking the bars together, creating a smooth-moving runway, suitable for many types of goods.

- Space saving: the cylindrical spiral design is an ideal solution for warehouses with limited area, helping manufacturing facilities maximize the use of vertical space

- Superior operating capacity: based on the automatic, continuous operation mechanism at high speed. The equipment can handle large volumes of products easily without any problems, which has made it a reliable device in many production facilities.

- Easy to use and customizable: the interface is easy to use and can be customized according to different needs, helping to meet many manufacturers’ requirements.

Disadvantages

In addition to the advantages mentioned above, spiral conveyors also have certain limitations such as:

- The movement direction is limited to one direction up and down.

- The belt is too long due to the high spiral shaft, so the frequency of maintenance is more than other equipment.

- The initial investment cost is quite expensive, but the operating efficiency and depreciation over many years are completely worth it.

What is the difference between screw conveyor and spiral conveyor?

Spiral Conveyor:

Spiral conveyor

- Uses traditional conveyor systems to move materials.

- Only moves vertically from top to bottom and vice versa.

- Uses belts for the entire operation.

- Cannot be heated or dried because they transport materials outdoors.

- Transports a wider variety of goods, including fragile goods.

Screw Conveyor:

Screw conveyor

- Uses a rotating screw inside a tube or trough to push materials from one place to another.

- Various directions of movement such as horizontal, vertical, or inclined.

- Uses rotating screw threads to move goods.

- Allows heating or drying of products as they move by controlling the atmosphere inside the tube.

- Suitable for transporting liquids or small solids.

Why choose the spiral conveyor solution at DNC?

There are many reputable spiral conveyor solution providers in Malaysia, but here are 4 reasons why you should prioritize choosing conveyor solutions at DNC Automation:

- We have a team of technicians with extensive experience in the conveyor and machinery automation industry.

- We always aim to invest and develop spiral conveyor lines in a modern, environmentally friendly, and energy-saving direction.

- Commit to 100% genuine products, with clear certificates and origins, fast delivery time, ensuring your production line operates stably and smoothly.

- We are ready to support and help you find the conveyor solution that suits your scale, needs, and budget.

If you have any questions, please contact us via the hotline below, we are happy to serve you!

- 68 views

- 0 Comment

Recent Comments