What Is a Slat Conveyor? Learn Features and Benefits for Plants

Slat Conveyor is an efficient and durable material handling solution in factories, especially in the heavy, food, pharmaceutical and electronics industries. With the ability to transport heavy, bulky or uneven materials, this conveyor system ensures high performance and flexibility. Specifications such as conveyor widths from 200mm to 1200mm, operating speeds up to 15 m/min and maximum loads from 50 – 300 kg/m make Slat Conveyor an ideal choice for many different applications.

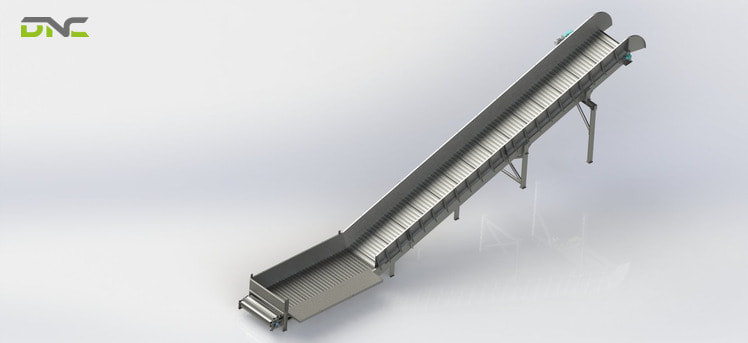

What is a Slat Conveyor?

A Slat Conveyor is a conveyor system designed with interconnected slats, usually made of durable materials such as steel, plastic or alloy.

This system uses slats to transport goods, especially items with large loads, uneven sizes or special shapes.

Slat Conveyors are widely used in industries such as manufacturing, fabrication, food, pharmaceuticals and warehousing.

Slat Conveyor Specifications

- Belt Width: 200mm – 1200mm

- Length: Can be designed according to requirements, usually from 2m to 30m or more.

- Height: Customized according to installation requirements, usually from 1m-1.5m.

- Conveyor speed: 0.5 – 15 m/min (can be adjusted by inverter)

- Conveyor frame: Powder coated steel or stainless steel

- Power: 0.2 – 3.7 kW

- Voltage: 220V or 380V

- Maximum load: 50 – 300 kg/m (depending on design)

- Warranty: 12 months

How many types of Slat Conveyors are there?

Slat Conveyors are not only diverse in size and material but also classified into many different designs to suit each purpose in the factory. Below are the 5 most popular types of Slat Conveyors today, each with its own unique characteristics to effectively meet the transportation requirements in the industry.

- Straight Slat Conveyor: The most popular type, the conveyor moves in a straight line. Suitable for assembly lines, packaging, or transporting products from point A to B.

- Curved Slat Conveyor: Designed in a curve (usually 30°, 45°, 90° …) to suit narrow factory spaces or need to redirect goods. Helps save space and is flexible in factory layout design.

- Elevating Slat Conveyor: Designed to transport goods up or down, often with anti-slip partitions. Applications in factories with many floors or warehouses that need to move vertically.

- Heavy-duty Slat: Use thick steel slat or special materials to transport heavy objects such as engines, large components, metal blocks, etc. Sturdy conveyor frame, large capacity chain.

- Plastic Slat Conveyor: Slat panels are made of high-strength plastic (POM, PVC), light, easy to disassemble and anti-corrosion. Often used in the food, pharmaceutical, beverage industries, etc.

5 most popular types of Slat Conveyors

What are the advantages of Slat Conveyors?

Slat Conveyors not only help transport goods effectively but also contribute to increasing production productivity. With flexible design and continuous operation, this system optimizes processes and reduces downtime. Below are the outstanding advantages of Slat Conveyors in improving factory productivity.

- High load capacity and high durability: With a sturdy structure and slat panels that can withstand large loads, Slat Conveyor is suitable for transporting heavy or unevenly sized products, helping to save costs and increase operating efficiency.

- Easy maintenance and low cost: Due to its simple structure, Slat Conveyor is easy to maintain and replace parts when necessary. This helps to minimize machine downtime and maintenance costs during operation.

- Continuous and uninterrupted operation: This is very important in production lines, where downtime needs to be minimized.

- High accuracy: Thanks to the automation of the transportation process, Slat Conveyor helps reduce human intervention, minimize human errors and increase accuracy in transporting goods.

- Space Saving: Slat Conveyors can be designed to transport products in confined spaces or on slopes and curves, optimizing space and production processes.

What are the advantages of Slat Conveyors?

What are the important notes when using Slat Conveyor?

To ensure that the Slat Conveyor operates stably, durably and safely throughout the production process, proper use is very important. Below are some necessary notes that businesses should pay attention to when operating this system.

- Periodic maintenance: Check the slat plates, bearings, conveyor chains and motors periodically to detect early wear or damage. Grease on schedule to ensure smooth operation of the system.

- Do not exceed the allowable load: Each Slat Conveyor system has its own load limit. Exceeding the load can easily cause the slat to bend, break or damage the transmission system.

- Keep the conveyor clean: Clean the slat plates regularly to avoid accumulation of dirt, grease or spilled products – especially in the food or pharmaceutical industry.

- Check the tension of the conveyor chain: Chains that are too loose can cause slipping or misalignment; Over tension causes rapid wear and energy consumption.

- Proper installation: Make sure the conveyor is installed on a stable surface, with a sturdy frame, to avoid vibration during operation.

- Disconnect power before maintenance: When cleaning, checking or replacing components, the power must be completely turned off to ensure the safety of the operator.

Compliance with the above notes not only prolongs the life of the Slat Conveyor system but also ensures safety and efficiency throughout the entire production process.

In which industries is Slat Conveyor commonly used?

Slat Conveyor is widely used in many industrial fields thanks to its ability to effectively transport goods of various shapes, sizes and loads. Here are some typical industries that apply Slat Conveyor:

- Mechanical manufacturing and assembly industry: Slat Conveyor is very suitable for transporting components, metal parts or finished products with large weight. This system is often integrated into the assembly line of automobiles, motorbikes, industrial machinery.

- Food and beverage industry: In the production of packaged food or bottled drinks, Slat Conveyor helps transport products quickly, cleanly and safely, meeting food hygiene requirements.

- Pharmaceutical industry: Slat Conveyor supports the transport of vials, blister packs or packaging with high precision, often used in automated packaging lines in the pharmaceutical industry.

- Electrical and Electronics Industry: Electronic circuit boards or electrical equipment can be easily transported by Slat Conveyor, helping to speed up assembly and product quality inspection.

- Warehousing and Logistics Industry: Slat Conveyor system supports the transportation of goods in the warehouse, helping to arrange and classify products easily, shortening order processing time.

Slat Conveyor is widely used in many industrial fields

Where to buy reputable automatic slat conveyor lines?

If you are uncertain about where to purchase a slat conveyor, DNC Automation is an excellent option for you. Many customers have trusted DNC to provide automation solutions in the production process and have had positive experiences because:

- DNC is a leading technology, automation, and engineering company in Malaysia with over 15 years of experience in the field of automation

- System integration machinery, Internet of Things (IoT), Industry 4.0, and WinCC Scada System

- Diverse designs and sizes are suitable for many domestic and foreign houses. The equipment is 100% genuine and imported from Malaysia.

Please contact us via the hotline below if you have any questions about the product, we are happy to answer you!

- 2 views

- 0 Comment

Recent Comments