Screw auger conveyor – High-quality and authentic 2024

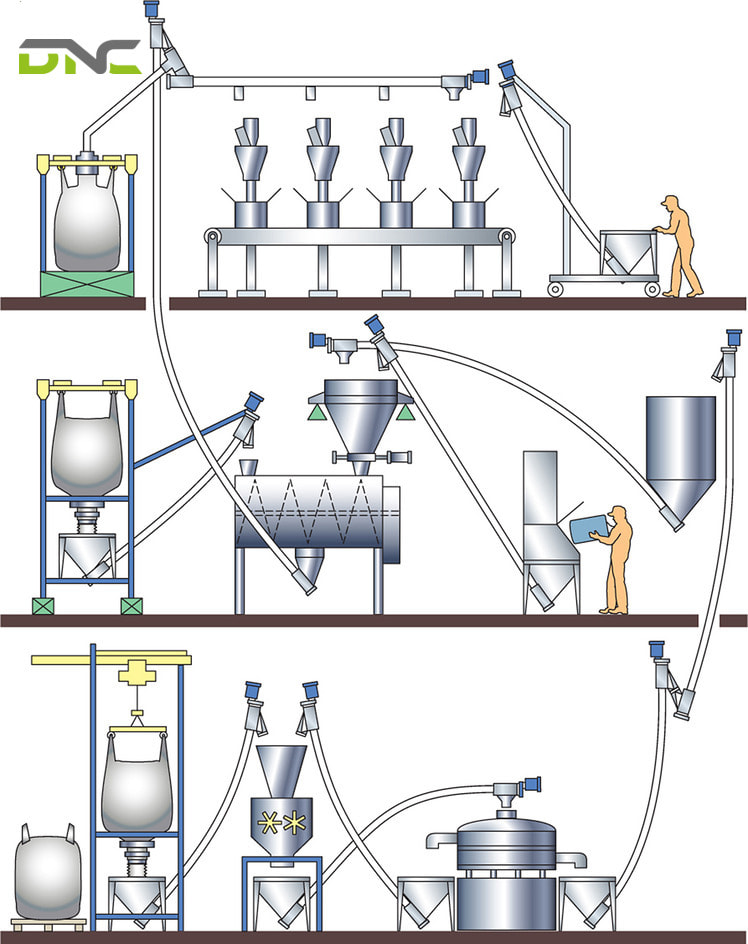

Invented around 1950, screw auger conveyors are specialized equipment for transporting large volumes of bulk materials, liquids, semi-solids, etc. from one part to another using rotating spiral screw blades. The equipment is capable of moving 18,000 cubic feet per hour, helping to increase production capacity for the factory.

If you are confused between choosing a screw auger conveyor and a tubular conveyor, this article will help you make the right choice. Besides, let’s find out the price and address to buy a reputable screw conveyor with DNC.

How many components make up a screw conveyor?

Screw conveyors are composed of 3 main parts as follows:

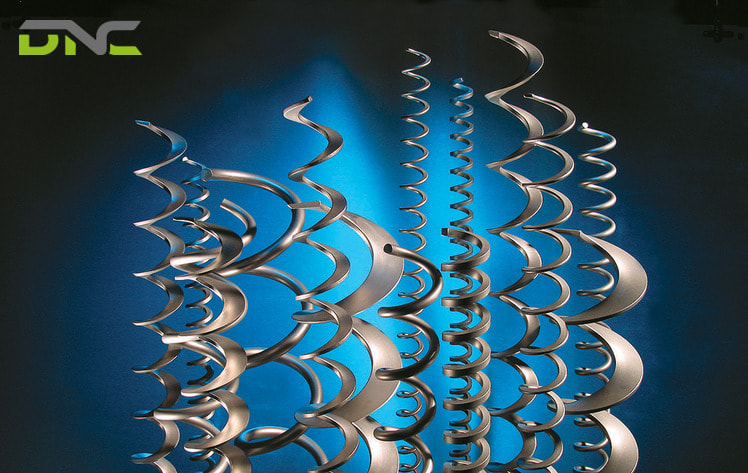

- Conveyor Screw: This is the most important part of a screw conveyor. It consists of a shaft with spiral blades around it, which is responsible for moving raw materials along the length of the trough. There are many types of screw conveyors such as Screw conveyor blades, flying screw conveyors, conical screw conveyors, etc.

- Trough materials: The trough surrounds the screw shaft and supports the storage of bulk materials during transportation, made of stainless steel. We can remove or expand the trough to protect the raw materials from pollution and dirt. There are many types of screw conveyors such as U-shaped troughs, rectangular troughs, tubular troughs, etc.

- Electric motor equipment: Automatic control according to pre-installed design programs.

Structure of screw auger conveyor

How many different types of screw conveyors are there?

Currently, screw auger conveyors are divided into 4 common types as follows: Horizontal screw conveyors, inclined screw conveyors, shaftless screw conveyors, and vertical screw conveyors.

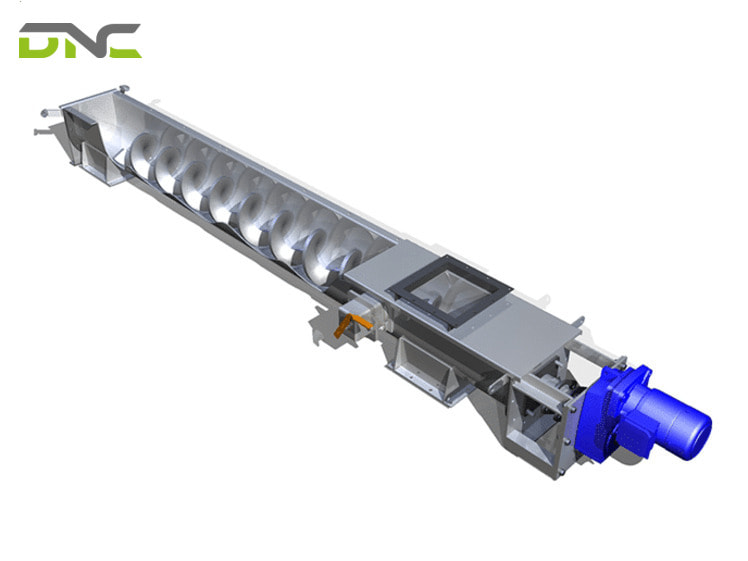

Horizontal screw conveyors

Horizontal screw conveyors are the most widely used type of conveyor. The main function is to transport bulk materials from one process to another.

- Suitable for transporting dry to semi-liquid bulk materials.

- More cost-effective than other types of conveying equipment.

- Completely closed system to avoid dust and corrosion.

- Using multiple input and output points helps to effectively distribute bulk materials to other parts.

Horizontal screw conveyors

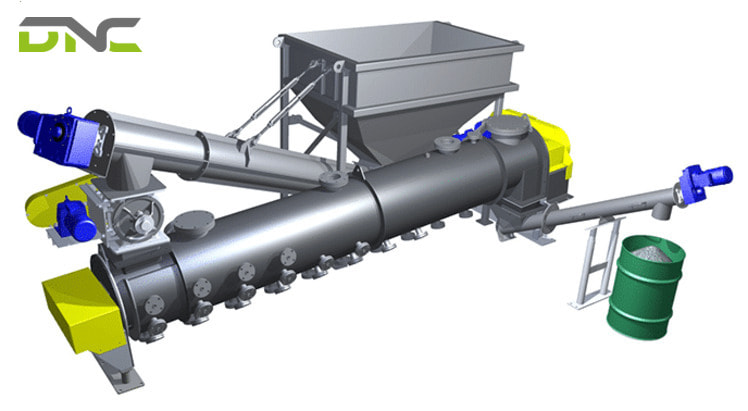

Inclined screw conveyors

Inclined screw conveyors are placed at a 45-degree angle to the ground. As the angle increases, the conveying efficiency decreases and the horsepower must be increased due to the impact of gravity.

- Lower installation costs than other conveyors

- Less likely to clog and jam

Inclined screw conveyors

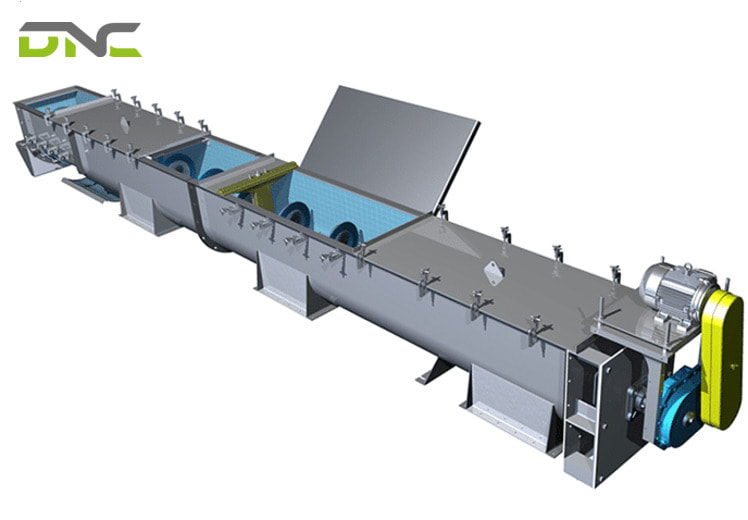

Shaftless screw conveyors

Shaftless screw conveyors make it easier to transport sticky materials because the shaftless design prevents clogging of the conveying surface.

- Suitable for transporting sticky and sluggish bulk materials.

- More efficient than other conveyors.

- Internal bearings are eliminated.

- Parts are easy to install.

Shaftless screw conveyors

Vertical screw conveyors

Vertical screw conveyors lift bulk materials at steep inclines or completely vertically.

- Suitable for transporting dry to semi-fluid materials.

- Capacity: 18.000 cubic feet per hour

- The enclosed design protects against dust and other contaminants

Vertical screw conveyors

What is the difference between a screw conveyor and a tubular drag conveyor?

Screw auger conveyors and tubular drag conveyors are two commonly used equipment in manufacturing plants because of their efficiency and convenience.

However, these two types of conveyors also have some differences in design and function. So how are they different? If you are curious about the answer to this question, continue reading to compare these two types of conveyors in detail.

Function

- Tubular drag conveyors are enclosed conveyors used to handle bulk materials such as granules, powders, grains, etc. Especially the ability to handle fragile materials without causing damage.

- Unlike tubular conveyors, screw auger conveyors are not suitable for transporting fragile materials. The simple reason is that the screw blades rotate directly through the materials, causing them to break, grind, and separate the mixture.

Cleaning and maintenance

- The tubular conveyor is equipped with a “clean in place” mechanism that allows for easy cleaning without disassembling the conveyor. In addition, the conveyor disc and cable can be easily replaced when necessary.

- The screw auger conveyor is not equipped with a “clean in place” mechanism, making cleaning more difficult and time-consuming. In addition, the internal components are susceptible to wear and tear due to handling heavy materials.

Transportation distance

- The tubular conveyor can be installed with a long-distance conveyor for more flexible transportation.

- The screw conveyor is more limited in terms of transportation distance because if installed too long, the raw material will easily get stuck in the conveyor.

Comparison of screw conveyor and tube conveyor

How much does a screw auger conveyor cost?

Is a screw auger conveyor expensive or cheap? This is one of the most common questions for buyers today. It can be said that this conveyor system has a more affordable price compared to other types of conveyor systems.

However, the price of a conveyor line depends on various factors such as operating capacity, technology, and design… Typically, the price of a tubular drag conveyor ranges from $5,000 to $10,000, depending on the production needs of the business.

Price of screw conveyor

Where to find high-quality, authentic screw conveyor solutions?

Currently, many businesses on the market provide automatic screw conveyor systems. At DNC Automation, we specialize in providing conveyor solutions with advanced technology, committed to high precision and efficiency in the production process. With the ability to be flexible and able to integrate with different equipment, DNC believes that we can bring many optimal solutions to your production facility.

Please contact us via the hotline below if you have any questions about the product, we are happy to answer you!

- 66 views

- 0 Comment

Recent Comments