Roller Conveyor System: Types, Structure, and Applications

The roller conveyor is a conveyor system consisting of a series of rollers arranged in series in a frame, forming a conveyor chain that helps move many different objects by gravity or force such as cartons, pallets, and plastic boxes…

Roller conveyor systems have many different classifications including Gravity rollers, Belt-driven rollers, and Chain-driven rollers…. Each type of conveyor will have different operating standards and prices, creating diversity for many customer segments.

In addition, this device has popular applications and many outstanding advantages. Thus, roller conveyors are indispensable equipment in large-scale warehouses and production lines.

How much does it cost to install a roller conveyor?

How much does a roller conveyor cost? For basic conveyors, the cost per foot will range from $100 to $200. For roller conveyors, which are specialized equipment for moving heavy goods, the price is usually between $200 and $500. However, don’t worry too much, this is just an estimate because many factors determine the cost of installing a conveyor line such as length, scale, performance, etc.

How much does it cost to install a roller conveyor?

What types of roller conveyors are there?

Gravity Rollers

This conveyor model has an affordable price and the level of advancement is also at the lowest level. Rollers are made of steel and are capable of transporting goods by gravity. This type of conveyor will have difficulty transporting heavy goods because the device does not have an integrated motor automatic.

Gravity rollers

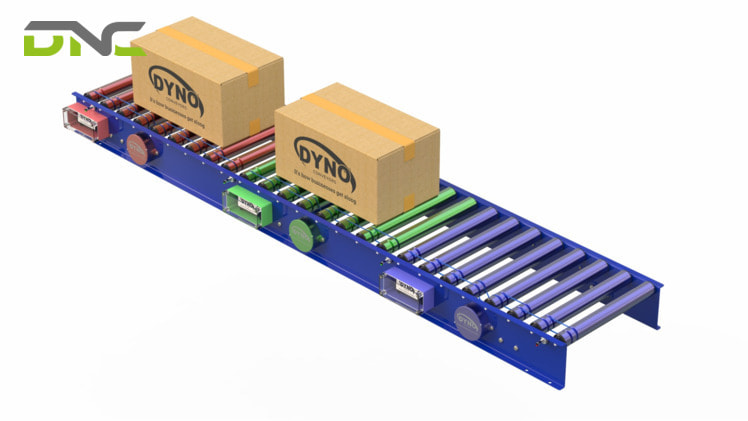

Belt-driven Conveyor Rollers

This is an MDR model that helps move goods without much effort. With a wider frame than gravity conveyors, belt-driven roller conveyors are suitable for transporting medium to high tonnage goods, helping the operator easily control the entire system, easily stop and change the belt direction as desired.

Belt driven conveyor rollers

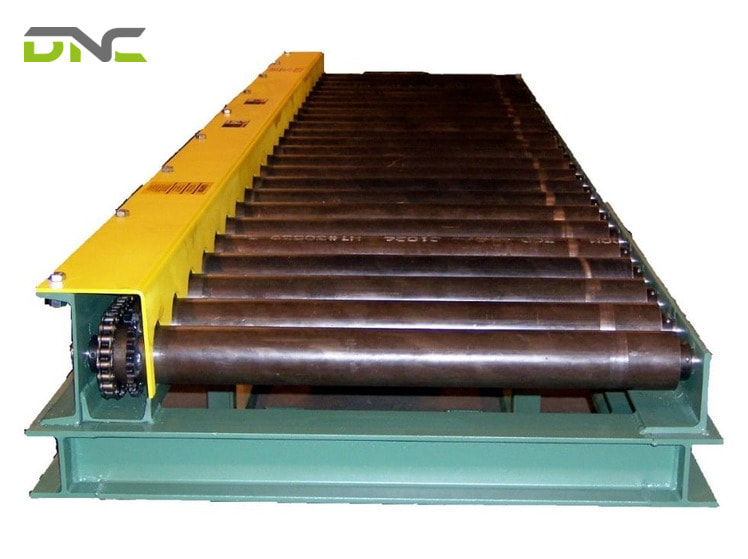

Chain-driven Conveyor Rollers

Has a similar operating mechanism to roller conveyors. However, they are said to be sturdy and widely applicable to a wider range of cargo sizes. In addition, the device can be easily turned and works well in wet conditions without any problems (if regularly maintained).

Chain driven conveyor rollers

Line Shaft Conveyor Rollers

This type of conveyor operates by combining individual urethane belt rollers and driving spools, with a variety of straight and curved designs, they operate virtually without making noise, suitable for many warehouse standards. A notable point is that this type of conveyor belt is not specialized for transporting heavy and bulky goods.

Line shaft conveyor rollers

Zero Pressure Conveyor Rollers

This is the most advanced and efficient type of roller conveyor today, equipped with sophisticated motors and sensors to control the entire conveyor area, creating a buffer zone between floors, preventing goods from touching. each other. each other during the trip. Although the price is higher than other types, this is still the top choice of many industrial factories because of the high sustainability and smart operation capabilities they provide.

Zero pressure conveyor rollers

Powered Conveyor Rollers

This conveyor classification is most suitable for warehouses that specialize in transporting light-weight goods. For every 10th roller there will be an internal motor that pushes the item forward to the manual rollers connected to an O-ring, so it will be a bit difficult to move heavy goods on the belt.

Powered conveyor rollers

What are the applications of roller conveyors?

Since the 1908s, roller conveyors have become more popular in production processes with many different applications such as:

What are the applications of roller conveyors?

- Applications in a variety of different industries such as packaging, manufacturing, filling…

- Support to help products move over large distances automatically without human participation.

- Ensure the safety of engineers and workers in the continuous transportation of many bulky and heavy goods.

- One of the indispensable parts of production and packaging processes, bringing convenience and saving significant time.

What are the benefits of roller conveyor chains?

Roller conveyors are the equipment of choice for many people because of their flexibility and variety of configurations. Since the early 20th century, the equipment has been widely used in many different industries with outstanding benefits:

Benefits of roller conveyor

- High adaptability and flexibility: whether temporary or fixed roller conveyors, the equipment meets the operating capacity well in a variety of locations such as warehouses, factories, airports, etc.

- Does not take too much time for maintenance and repair: because the machine has a simple structure and the process has very few moving parts, limiting downtime when handling goods.

- High-cost efficiency: roller conveyors are very durable equipment, so the initial investment cost, although a bit high, is completely worth it after many years of depreciation.

- Increased working efficiency: thanks to the conveyor belt automatically moving goods over long distances, saving time and providing higher safety compared to other manual methods of moving goods.

What should be noted before choosing a roller conveyor?

To install a suitable and functioning roller conveyor system, you should keep in mind a few important things such as:

Some notes before choosing roller conveyor

- System speed: for typical conveyor systems, speed remains around 65 feet per minute. However, you can consider this issue based on the current facility size to choose a suitable conveyor chain and meet high performance.

- Load capacity: The load capacity of the line greatly affects the entire system. If you choose lines with inappropriate load capacity, it will cause overload, causing the system to malfunction and stop working.

- Factory space: Manufacturers should carefully consider the size of the current facility to choose appropriate roller conveyor systems, avoiding taking up too much space and affecting neighboring equipment.

- Transmission system: is the factor that determines the ability and direction of goods movement, fast or slow, and can move in one or more directions…

- Roller frame material: usually the material is usually made from aluminum or steel, others are coated with plastic or rubber to increase friction. This issue depends on the material of the goods being transported. Choosing rollers with the appropriate material will bring about a more complete moving process.

- 115 views

- 0 Comment

Recent Comments