As a specialist in heavy industry machinery, DNC provides the solution for the glove industry to provide High Efficient and Energy Saving Systems.

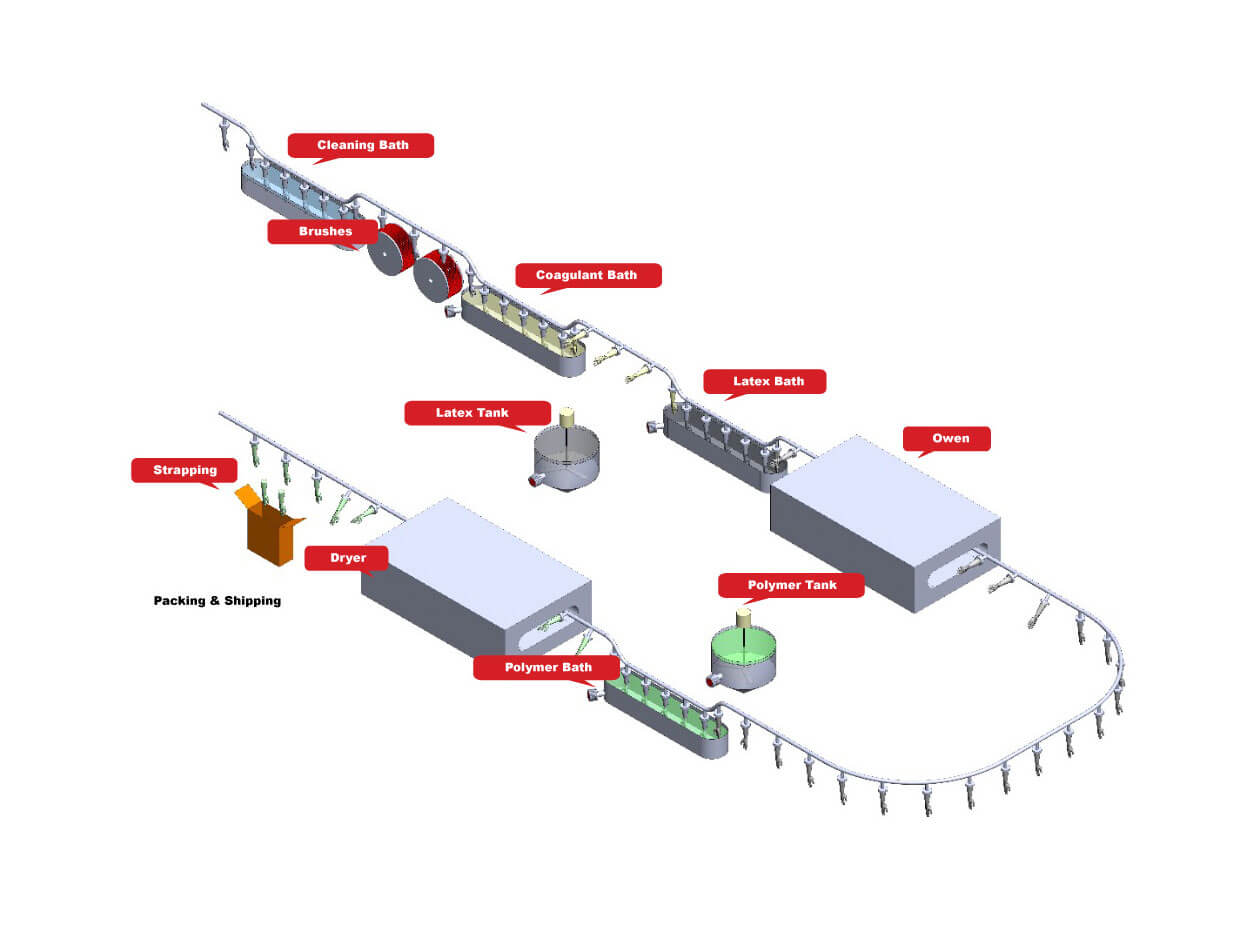

The flow of the production process of latex glove is former cleaning, coagulant dipping, drying, latex dipping, leaching, beading, vulcanizing, post leaching, slurry dipping, stripping, tumbling, and quality control.

Former Cleaning

Before the latex can be process to the coagulant dipping process into hand-shaped, the glove formers need to be cleaned before it can be used to form hand-shaped latex gloves. A quality production of exam gloves includes the environment of latex glove factory is clean.

Coagulant Dipping

After the glove former is cleaned, it will be coated with coagulant (eg. calcium nitrate) and be dipped into the coagulant bath to help the latex mixture adhere to the formers and to help ensure the latex is distributed evenly.

Drying

Drying is one of the stations in production process of latex gloves manufacturing whereby the coagulant converts the liquid latex film into a wet-gel on the glove formers and will eventually travel through a series of ovens to dry the gloves and end the coagulation process.

Latex Dipping

Latex dipping is one of the stations in the production process of latex gloves manufacturing and the tank is filled with compounded latex. A latex layer will be formed on the glove former after it goes through this tank. The thickness of the latex glove is determined at the coagulating and dipping stage.

Leaching

This leaching stage can called as the pre-vulcanization leaching. It also known as “wet gel leaching”. Residual chemicals and proteins on the surface of the gloves are put into the leaching process to be removed after the drying of latex mixture.

Slurry Dipping

This stage is also known as “wet even powdering”. The slurry tank containing the cornstarch solution can prevent latex gloves from sticking in the tank. The slurry is also referred to as wet powder. The benefit of this powder is acting as preservation of the latex gloves and to assist in the latex gloves donning process.

Stripping

At this stage, the latex gloves are stripping from the glove formers. There are two types of methods, which are manually or automatically stripping the latex gloves from the glove formers.

Tumbling

The tumbling process at latex gloves manufacturing process is to remove excessive powder on the gloves. The latex gloves are putting into the commercial dryers to ensure that the powder is more evenly distributed and excess powder can be removed.

Quality Control

DNC carries out its quality control in total quality management system. In total quality management system, we using vision system to provide inspection system to help control in glove quality and reject defeat glove.