Chain Conveyor: A Reliable Solution for Industrial Material Handling

Chain conveyors play a critical role in modern automation systems by enabling stable, controlled, and heavy-duty material movement. Understanding how these systems work and where they perform best helps businesses design efficient, scalable, and reliable material handling operations.

What is a chain conveyor?

A chain conveyor is a mechanical material handling system that uses one or more continuous chains to transport products along a fixed path. Unlike belt or roller conveyors, chain conveyors are designed to move heavy, bulky, or rigid loads with consistent positioning and high durability. They are commonly used in industrial environments where strength, precision, and long service life are essential. Chain conveyors can operate horizontally, vertically, or on inclines, making them suitable for complex production layouts. Their robust construction allows them to function reliably in demanding conditions such as high temperatures, dusty areas, or heavy manufacturing processes.

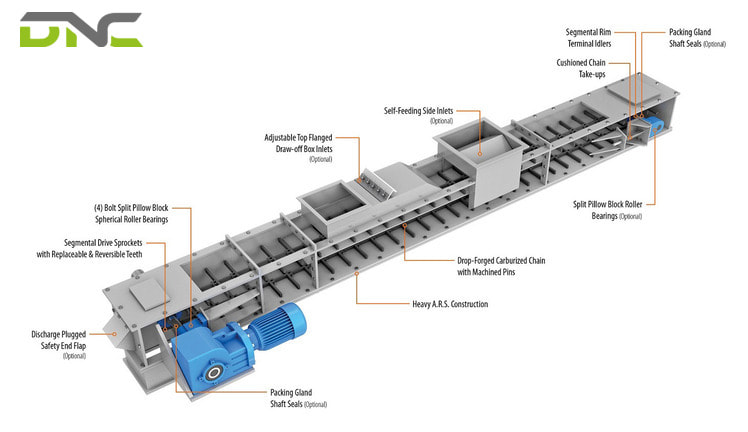

What are the main components of a chain conveyor?

The chain conveyor has a fairly simple structure, consisting of 4 main parts: Frame & support system, chain conveyor belt, controller, and motor.

- Frame & support system: Usually made of powder-coated steel or 304 stainless steel with a thickness of 2-5mm. The larger the thickness, the greater the load capacity, helping to ensure a sturdy and stable loading speed for the entire system.

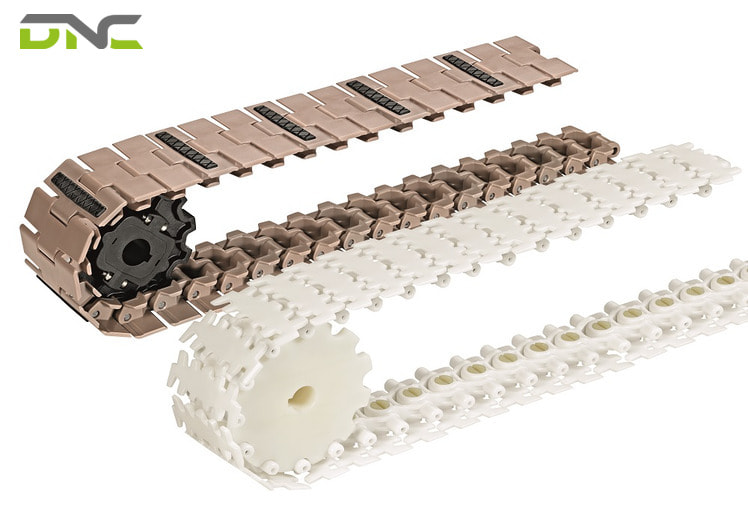

- Chain conveyor belt: This is the main transmission part, it is made of chain links linked together. The belt surface can be made of plastic or stainless steel depending on the working environment.

Chain conveyor belt

- Controller: The controller integrates a PLC touchscreen for easy management and remote monitoring of the production process. There are also sensor buttons, indicator lights, and speed control buttons.

- Motor: Gear motor with capacity depending on transmission speed such as 0.75KW, 1.2KW,…

- Some other parts: Feed hopper, heat drying powder set, lighting,…

Detailed structure of chain conveyor

How does a chain conveyor work?

Chain conveyors operate using a simple yet highly effective mechanical principle. The movement of the chain ensures stable load transfer across different stages of production or storage.

- Drive mechanism and chain movement: The system uses a motor-driven sprocket to pull the chain along a predefined track. As the chain moves, it carries products that are either placed directly on the chain or supported by fixtures attached to it.

- Load support and guidance: Products remain stable during transport because the chain follows a fixed guide path. This controlled movement is ideal for handling pallets, metal components, or large containers without slipping or misalignment.

- Continuous or indexed operation: Chain conveyors can operate continuously for constant flow or in indexed motion for precise positioning. This flexibility makes them suitable for automated assembly, inspection, and packaging lines.

How many types of chain conveyors are there?

Chain conveyors are widely used in factories because of their efficiency and convenience. To meet the needs of each customer, chain conveyors are divided into many different types with different functions

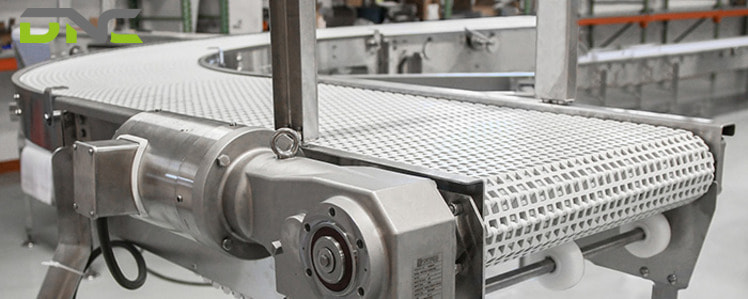

Plastic chain conveyors

- This is one of the most commonly used conveyor systems. With a simple design, easy to install and transport on many different types of terrain

- Plastic chain conveyors are often used in the food, beverage, pharmaceutical, and light and medium industries. Where environmental conditions require cleanliness and no pollution.

Plastic chain conveyors

Stainless steel chain conveyors

- The conveyor is designed with a chain conveyor made of stainless steel (stainless steel 304) that can withstand high abrasion. The stainless steel mesh surface can withstand high temperatures, outstanding with effective anti-corrosion and rust resistance.

- Stainless steel chain conveyors are often used in harsh environments: Wood, soil, cement, bricks, stones, ores, etc. They are also very suitable for transporting frozen products.

Stainless steel chain conveyors

Wooden chain conveyors

- The conveyor is made of sturdy wooden bars, providing stability and durability. To ensure maximum performance, only carefully treated natural wood is used. These wooden bars have been soaked in a fire-retardant solution, ensuring abrasion resistance and high-temperature resistance.

- Wooden chain conveyors are often used to transport cosmetics, food, cartons, etc.

Wooden chain conveyors

Chain conveyor vs other conveyor types

Choosing the right conveyor system depends on factors such as load type, operating environment, and automation requirements. While chain conveyors are known for strength and durability, other conveyor types may be better suited for lighter or high-speed applications. The comparison below highlights the key differences to help identify the most suitable solution.

|

Compare the difference between chain conveyors and belt conveyors

Are chain conveyors expensive or cheap?

The price of automatic vertical conveyor lines on the market usually fluctuates between $10,000 – $15,000. However, this price can still change depending on several factors such as:

- Brand: Each brand may have different prices, depending on pricing policies, operating costs, and accompanying services.

- Goods: Each type of goods will be suitable for a different type of chain conveyor. Businesses need to determine what they are trading to make the most accurate choice.

- Chain conveyor size: For factories with large capacity, a large conveyor size is needed to optimize the transportation process. The larger the size, the higher the price.

To know the exact price of vertical conveyor lines at present, you should contact the suppliers directly for advice and specific quotes.

Chain conveyor price

Where to Buy the Best Chain Conveyors in Malaysia?

If you are uncertain about where to purchase vertical conveyor belts, DNC Automation is an excellent option for you. Many customers have trusted DNC to provide automation solutions in the production process and have had positive experiences because:

- DNC is a leading technology, automation, and engineering company in Malaysia with over 15 years of experience in the field of automation

- System integration machinery, Internet of Things (IoT), Industry 4.0, and WinCC Scada System

- Diverse designs and sizes are suitable for many domestic and foreign houses. The equipment is 100% genuine and imported from Malaysia.

Please contact us via the hotline below if you have any questions about the product, we are happy to answer you!

- 64 views

- 0 Comment

Recent Comments