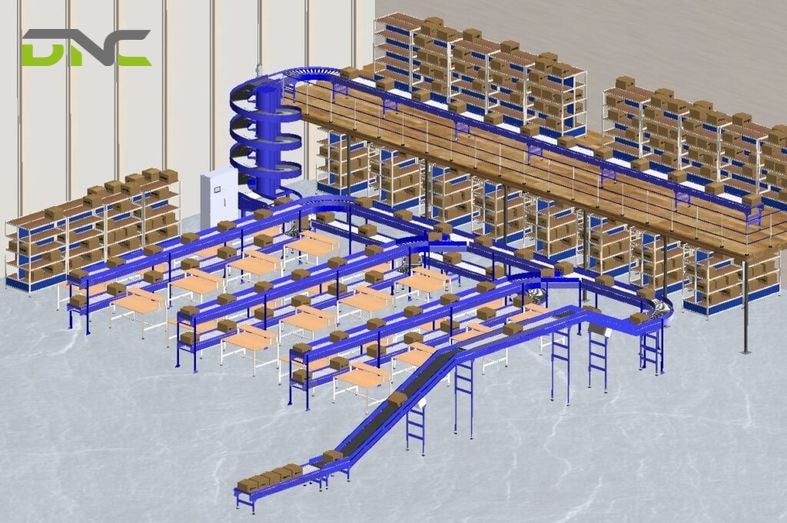

Conveyor Belt Sorting System – The Most Modern Conveyor Belt Today

In today’s fast-paced industrial and commercial environment, automation is key to achieving efficiency, consistency, and speed. One of the most advanced advancements in this field is the Conveyor Sorting System, a state-of-the-art solution designed to streamline the sorting process in a variety of industries.

A sorter conveyor is an automated material handling system that identifies, sorts, and guides products or items to designated locations. Using technologies such as barcode scanners, RFID readers, sensors, and vision systems, intelligent sorters separate products based on size, weight, destination, or type.

Whether in a busy e-commerce warehouse, a food packaging plant, or a postal sorting facility, a sorter conveyor dramatically reduces manual labor and is a reliable piece of equipment that every business should own.

What are the applications of sorting conveyors?

What are the applications of sorting conveyors?

Sorting conveyor systems are incredibly versatile and widely used in industries where speed and accuracy are essential. Let’s explore the most common fields where these systems are transforming operations:

- E-Commerce and Logistics: In fulfillment centers and parcel hubs, sorting conveyors are critical for managing the massive volume of packages. They automate the process of sorting orders by zip code, delivery route, or customer, drastically reducing handling time and improving shipping accuracy.

- Food and Beverage Industry: Sorting conveyors are used to classify food products based on weight, size, shape, or type. For example, they can separate ripe from unripe fruit or remove damaged items from a production line, ensuring only quality products make it to packaging.

- Manufacturing: Manufacturers use sorting conveyors to route components to specific assembly lines or workstations. This improves workflow efficiency, especially in high-volume production environments like automotive or electronics manufacturing.

- Pharmaceutical and Health Products: In pharmaceutical production, sorting conveyors help in packaging and labeling processes by directing products to the correct bins based on batch, dosage, or packaging type, ensuring compliance and safety.

Specifications of the sorting conveyor

When selecting and installing a baggage conveyor system in an airport or factory, understanding the technical parameters is very important to ensure the system operates stably and meets operational requirements.

- Conveyor belt size: 1200mm – 30000mm – 1000mm (Width – Length – Height), can be adjusted according to business requirements

- Frame: Stainless steel (Inox), powder-coated steel or aluminum profile.

- Belt: PVC or industrial rubber, high durability, anti-slip, and good load capacity

- Maximum load: 50 – 100 kg/m (depending on roller and motor design)

- Conveyor speed: 0.3 – 0.9 m/s (adjustable by inverter)

- Power source: 220V – 380V, 50Hz

- Motor: 0.75kW – 3kW depending on length and load

- Safety features: Emergency stop button, sensor to detect obstacles/stuck luggage, and Integrated overload warning system.

- Warranty: 12 months

What types of sorting conveyor are there?

What types of sorting conveyor are there?

There are several types of sorting conveyors, each suited for different types of materials and sorting requirements. The most popular types include:

- Flat belt sorting conveyors are one of the most basic and widely used conveyor systems. They consist of a continuous flat belt stretched over pulleys and driven by a motor. In sorting applications, sensors and diverters are installed along the conveyor to direct items into the correct trough or area.

- Roller conveyors for sorting have a series of rollers supported in a frame. They can be powered (motorized rollers) or unpowered (gravity-based). For sorting, pop-up rollers, pushers or diverters are often added between the rollers to direct items in different directions.

- Modular plastic belt conveyors use interlocking plastic belt segments that provide great flexibility and hygiene. The modular design allows the conveyor to bend and tilt as needed, making it ideal for sorting in compact or irregular layouts.

- Inclined/tilted sorting conveyors are used to move items between different heights while performing sorting. They are often equipped with tie bars or textured surfaces to prevent items from slipping when moving vertically.

What are the advantages of a sorting conveyor?

What are the advantages of a sorting conveyor?

Sorting conveyors are trusted equipment because they offer many benefits to modern operations. Some of the key advantages of the equipment include:

- Improved efficiency: Automated sorting is much faster than manual processing, allowing companies to meet high throughput demands, especially during peak seasons or production spikes.

- Improved accuracy: With advanced sensors and tracking systems, sorting conveyors help reduce errors, ensuring each item is delivered to the right location.

- Reduced labor costs: By automating repetitive tasks, companies can reduce their reliance on manual labor, redirect employees to higher-value activities, and reduce operating costs.

- Optimize space: With the ability to route products over curves, inclines, and gradients, sorting conveyors can make the most of available space in compact facilities.

- Safe and Clean: Minimizing manual handling not only improves safety by reducing repetitive lifting and strain but also maintains a cleaner and tidier work environment.

Where can you buy the most reputable sorting conveyor?

There are many sorting conveyor solution providers in Malaysia, but here are 4 reasons why you should prioritize choosing sorting conveyor solutions at DNC Automation:

- We have a team of technicians with extensive experience in the conveyor and machinery automation industry.

- We always aim to invest and develop conveyor lines in a modern, environmentally friendly, energy-saving direction.

- Commit to 100% genuine products, with clear certificates and origins, fast delivery time, ensuring your production line operates stably and smoothly.

- We are ready to support and help you find the conveyor solution that suits your scale and needs and is within your budget.

If you have any questions, please get in touch with us via the hotline below. We are happy to serve you!

- 1 views

- 0 Comment

Recent Comments