What is the lifter conveyor? How much money for the lifter conveyor?

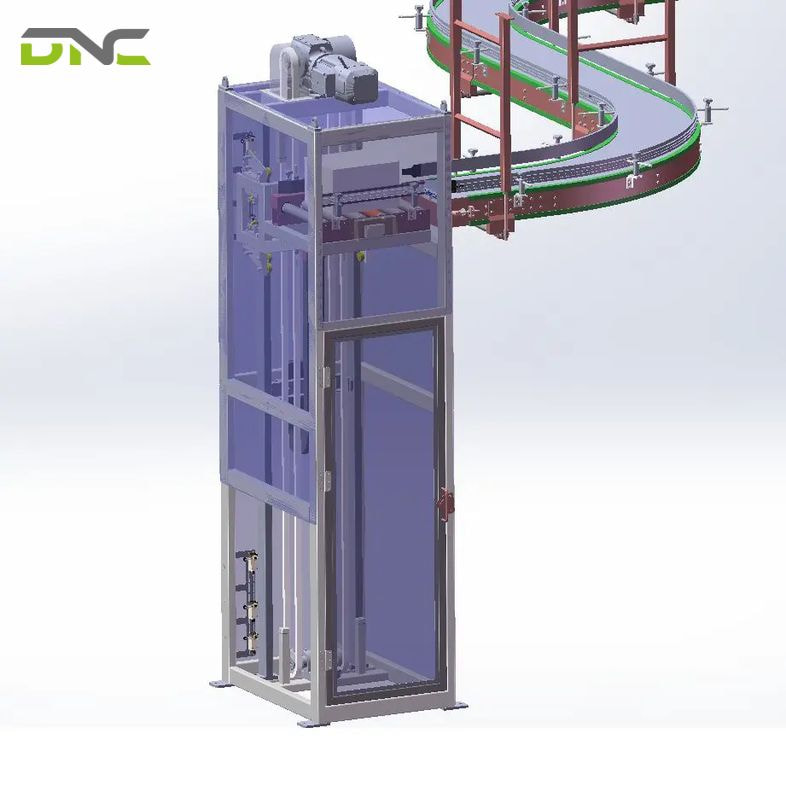

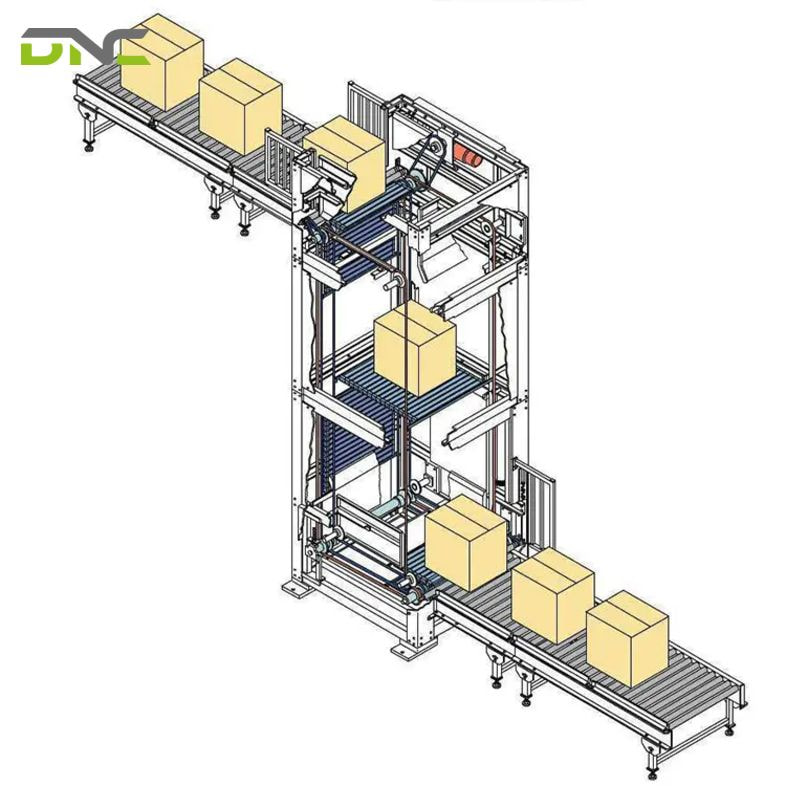

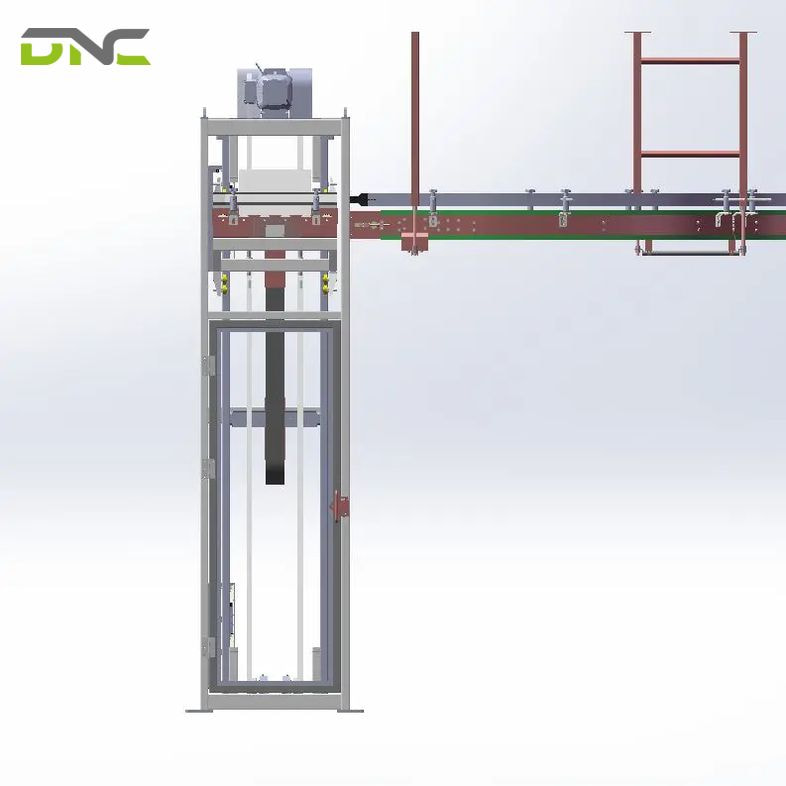

What is the lifter conveyor? In the world of automation, lift conveyors are quite commonly used. This equipment is also known as a lift conveyor or vertical conveyor. This machine is designed to transport materials or goods vertically between different floors. Whether moving cartons in a warehouse or moving parts in a production line, lift conveyors are all about efficiency and space optimization.

A lift conveyor consists of a frame structure, a lifting mechanism (such as a belt, chain or scissor lift), a platform or bucket to hold the items, and a mechanical system to power the movement, creating the most optimal goods transportation process possible.

Why should you choose a lifter conveyor to transport goods?

The lifting conveyor is designed to maximize the process of transporting goods between different floors with minimal manual handling. This not only helps to limit risks during the working process but also creates uniformity in the quality of the products. Some outstanding advantages of the lifting conveyor make many people trust it:

- Space saving: Instead of having to arrange ramps or install bulky lifts, the lifting conveyor allows goods to be transported vertically in a very small area.

- Reduce labor: The system operates completely automatically, helping workers not need to use their hands or forklifts to move goods up and down.

- Increase productivity: When goods are lifted or lowered continuously without having to stop, the work process becomes more seamless and efficient. The speed of order processing, packaging, or production is also significantly improved compared to using manual equipment.

- Safer: Limiting human intervention in the lifting process reduces the risk of work accidents, such as slipping, colliding, or lifting too much. The lifting conveyor is designed with sensors, protective frames, and emergency stop systems, ensuring safety during operation.

- Easy to integrate: The lifting conveyor can be directly connected to horizontal conveyors, spiral conveyors, or automatic packaging and sorting systems. This makes it easy for businesses to expand the line without changing the existing system as a whole.

Technical specifications of the lifter conveyors

Technical specifications of the lifter conveyors

Lifter conveyor specifications may vary depending on each company’s application and specific requirements. Here are some basic specifications:

- Conveyor size: 3m x 12m (Width x length), can be designed according to requirements

- Material: Galvanized steel or black steel, Stainless steel 304 or 316 (for food and pharmaceutical industries)

- Maximum load per roller: 50kg – 200kg, depending on the size and material of the roller.

- Total load of conveyor belt: 500kg – 1000kg/m (or more, depending on requirements)

- Travel speed: 0.5m/s – 1.5m/s.

- Warranty: 12 months

Which industries can apply lift conveyors?

Thanks to their convenience and versatility, lift conveyors have been widely used and applied in many fields, from warehouses to food export

- Warehousing and logistics, lift conveyors help move boxes or packages between floors or from loading areas to storage racks.

- Assembly lines – equipment that will transport raw materials to a specific machine or processing line before continuing production.

- The food and beverage industry, especially in the packaging stage. Bottled drinks are transferred from the filling machine to the labeling machine on the upper floor in an automated manner.

- Pharmaceutical manufacturing uses lift conveyors under strict hygiene conditions. The ability to transport delicate products or materials without human contact

In general, lift conveyors are used in any industry that requires vertical transportation, making them a valuable and highly versatile automation device in many fields.

How much does a lifter conveyor cost?

How much does a lifter conveyor cost?

How much does a lifter conveyor cost? This is a common question because, like most automation solutions, the price of a lift conveyor depends on a number of factors, including size, complexity, materials, and customization.

- For basic setups, expect to pay around $2,000 to $5,000. These are typically compact systems designed for light materials and short vertical distances, often used in smaller operations or light-duty applications.

- If your needs are more demanding, requiring heavier loads or covering greater heights, the cost will increase. Mid-range systems with higher load capacities and more automation features can cost between $8,000 and $15,000.

- Additionally, fully customized, high-performance systems can cost well beyond $20,000. Especially if they are integrated into a larger conveyor line or include sensors, smart controls, or a stainless steel frame for sanitary environments.

In short, the cost of a lift conveyor depends on the size and needs of your operation, but it is an investment in long-term efficiency, safety, and productivity.

What should be noted when using a lifting conveyor?

What should be noted when using a lifting conveyor?

To get the most out of your investment and a quality elevator system, you need to operate and maintain it properly. As with any machine, some best practices will go a long way.

- Do not overload the system. Every elevator conveyor has a certain load capacity, and exceeding that capacity can damage the motor, shorten the life of the system, or worse, create a safety hazard.

- Regular maintenance includes checking the belt or chain, inspecting the motor, cleaning the platform, and lubricating components as needed. Preventive maintenance can prevent costly breakdowns.

- Be thorough in food, beverage, or pharmaceutical environments. Choose models with easy-to-clean surfaces and make sure to follow a strict cleaning schedule.

- Highly skilled technicians are needed because, although elevator conveyors are largely automated, they still require someone to monitor their operation, troubleshoot, and stop them if necessary.

- Pay attention to safety, install guards where necessary, use signs, and do not allow unauthorized personnel to operate the system.

To use a conveyor safely and efficiently, you need to follow loading instructions, perform regular maintenance, keep the conveyor clean, and make sure your team knows how to use the conveyor properly.

Where can you buy the automatic lifting conveyor?

There are many reputable conveyor solution providers in Malaysia, but here are 4 reasons why you should prioritize choosing lifter conveyor solutions at DNC Automation:

- We have a team of technicians with extensive experience in the conveyor and machinery automation industry.

- We always aim to invest and develop conveyor lines in a modern, environmentally friendly, energy-saving direction.

- Commit to 100% genuine products, with clear certificates and origins, fast delivery time, ensuring your production line operates stably and smoothly.

- We are ready to support and help you find the conveyor solution that suits your scale and needs and is within your budget.

If you have any questions, please get in touch with us via the hotline below. We are happy to serve you!

- 0 views

- 0 Comment

Recent Comments