What is a Screw Conveyor? Interesting Facts About Screw Conveyors

What is a screw conveyor? The screw conveyor is a mechanical device used to move bulk materials in a controlled and efficient manner. The design consists of a rotating helical screw blade, which is placed inside a cylindrical or U-shaped trough. As the screw rotates, it pushes the material forward through the closed system. The motion is powered by an electric motor connected to the screw shaft.

Screw conveyors are a common device in many fields such as the production of powders, granules, granules or semi-solid materials that need to be transported horizontally, vertically or at an incline. Due to their simplicity, reliability, and versatility, this product is widely used and trusted in many production and modern life fields.

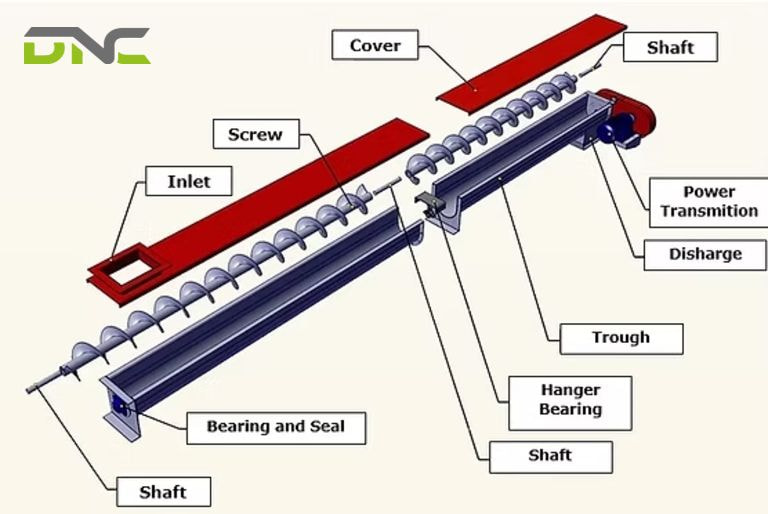

What are the parts of a screw conveyor?

What are the parts of a screw conveyor?

Screw conveyors are not very complex in construction, some typical components that make up a screw conveyor are: screw shaft, housing, drive motor, inlet and outlet.

- The screw shaft is the central working part of the conveyor. It can have many shapes depending on the material being transported. With the operating mechanism being to rotate along its axis, pushing the material forward through the system, the distance of the shafts can be adjusted to control the flow rate.

- The trough or Housing is the container that encloses the screw shaft. It can be U-shaped for an open-end design or completely enclosed in a tube housing. The type of housing affects how the material is contained, especially for dusty or hazardous materials. Materials such as stainless steel, carbon steel, or plastic can be used depending on the application.

- Drive motor: The drive usually consists of an electric motor, a speed reducer and a coupling that together rotate the screw shaft. The motor power is selected based on the material type, conveyor length, and incline angle.

- The inlet and outlet ports are the entry and exit points for the material. Depending on the process layout, the conveyor may have multiple inlets and outlets. This design allows flexibility in routing materials and integration into larger systems.

What types of screw conveyors are there?

Screw conveyors come in a variety of designs, each suited to a specific use case and material characteristics, some of the most common types today are Horizontal and Inclined Screw Conveyors, Shaftless Screw Conveyors, and Shaftless Screw Conveyors:

horizontal-and-inclined-screw-conveyors

Horizontal screw conveyors are the most widely used type. They move materials efficiently over short to medium distances and are ideal for feeding materials evenly and consistently to downstream processes. These systems typically operate at a slight incline (up to 10°) when material needs to be lifted.

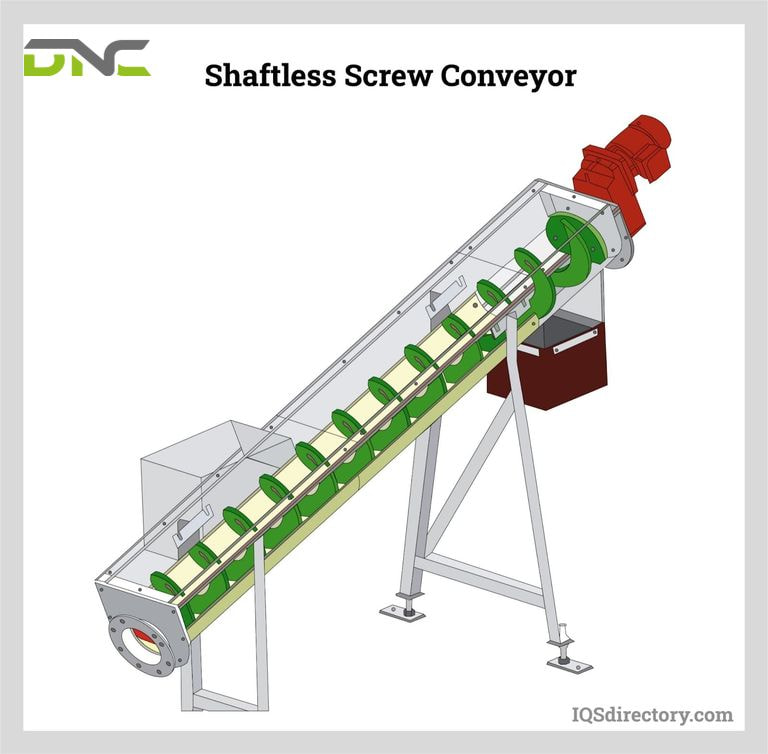

Shaftless Screw Conveyors

Shaftless Screw Conveyors

Shaftless screw conveyors eliminate the central shaft commonly found in traditional designs. They use rigid, flexible steel spirals, which are better suited to difficult materials such as sticky sludge, fibrous food waste, or irregular particles.

These conveyors are particularly popular in wastewater treatment and food processing. No shaft, less risk of clogging, easier to clean, and better material handling.

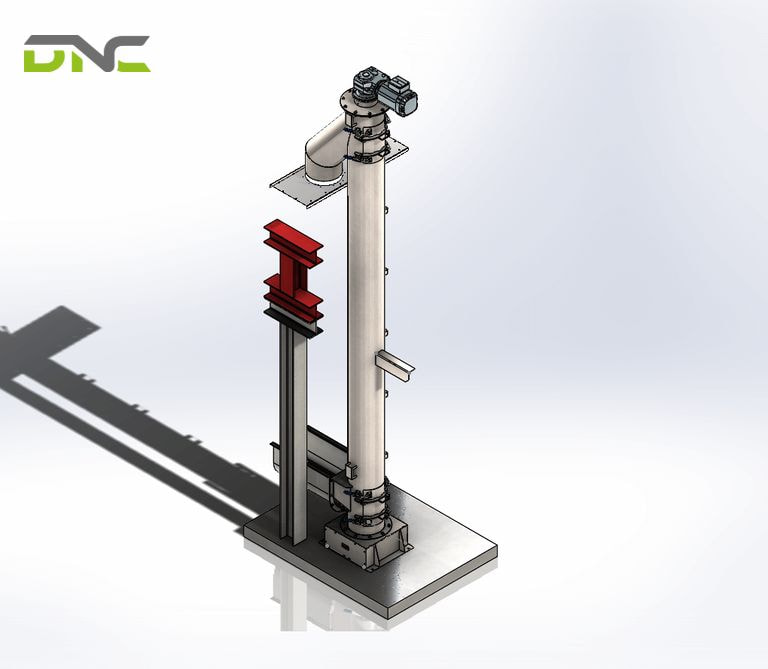

Vertical Screw Conveyors

Vertical Screw Conveyors

Designed to lift materials vertically, these systems are a space-saving solution in compact facilities. Vertical screw conveyors typically transport materials from floor to floor or from above-ground storage to overhead bins. This classification is very effective for fine, dry materials.

What are the features of screw conveyor?

As mentioned earlier, Screw Conveyors are popular for their convenience and versatility. In addition, some of the outstanding features that make them an ideal solution in many industries need to be listed as follows:

- Versatility: They can handle an incredible variety of materials, granules, slurries, and pastes, making them easy to adapt to almost any process.

- Compact and simple design: Screw conveyors take up less floor space than conveyor or pneumatic systems, and can be installed in tight locations, saving space.

- Closed system: The sealed nature of screw conveyors helps prevent spills, reduces dust, and protects workers from exposure to harmful materials.

- Controlled feed rate: The equipment can be pre-programmed by adjusting the screw pitch, rotation speed, or tilt, making it easy for the operator to observe and fine-tune the material flow to meet the requirements of the process.

- Cost-effective maintenance: With fewer moving parts and relatively simple construction, maintenance is often easy and inexpensive, especially when constructed with wear-resistant materials.

Where are screw conveyors commonly used?

Where are screw conveyors commonly used?

Screw conveyors are used in many different industries such as agriculture, food industry, waste management…

- Agriculture: An indispensable component for transporting grain, seed, flour or animal feed in silos and large-scale barns.

- Food industry: equipment supports the movement of dry ingredients such as sugar, salt, flour, and even wet products such as crushed vegetables or sauces.

- Mining and minerals: Transporting crushed ore, sand, or fly ash in mining operations.

- Waste management: Used in the transport of waste such as dewatered sludge, biological waste, or organic matter in treatment plants.

- Construction: Widely used in construction sites, specializing in transporting cement, gravel, or bentonite in construction and drilling applications.

Depending on the industry, the design of the screw conveyor can be customized to meet strict hygiene, temperature or material handling standards to deliver the highest performance to the user.

What are the limitations of screw conveyors?

Although screw conveyors have many advantages, they are not always the best solution for every application. There are certain product limitations that users should be aware of when using them:

- Limited distance and capacity: They are ideal for short to medium distances. For longer distances and heavier loads, manufacturers should prioritize other types of conveyors to ensure production efficiency.

- High wear rate: Raw materials during transportation can directly wear out the motor and housing. This can add time and cost to equipment maintenance.

- Heat dissipation: Friction between the screw and the material can generate heat, which can affect sensitive materials such as food or chemicals during production and transportation.

- Not ideal for all angles: Beyond 45° incline, screw conveyors become less efficient, require more power and require much more specialized design considerations.

Understanding both the strengths and weaknesses of screw conveyors will ensure that manufacturers can easily implement the right process and application, ensuring high performance with long service life

- 0 views

- 0 Comment

Recent Comments