5 Reasons to Choose Overhead Conveyor for Your Factory

Overhead Conveyor is an automation solution that saves space and optimizes productivity in factories. This system not only transports products flexibly but also easily integrates with other automation technologies. Let’s explore the advantages, disadvantages and compare with other types of conveyors with DNC Automation to better understand the efficiency of this system.

What is an Overhead Conveyor?

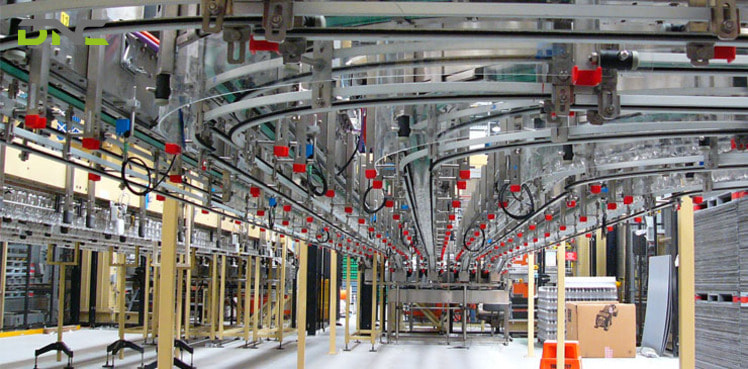

An Overhead Conveyor is a cargo transport system installed above the workspace, using chains, rails and hooks to move products along a predetermined route.

This system helps optimize factory floor space, increase production efficiency and reduce labor costs. Overhead Conveyors are often used in industries such as automobile assembly, coating, textiles, food processing and logistics.

How many parts does an Overhead Conveyor consist of?

The Overhead Conveyor system consists of 5 main parts, each of which plays an important role in ensuring the efficient and continuous transportation of products. Let’s explore these components in detail to better understand the operating mechanism of the system.

Hanging rails

Hanging rails are the main components of the Overhead Conveyor conveyor system, acting as a path for products to move.

These hanging rails are usually made of sturdy steel and are mounted on the ceiling or on rigid racks, ensuring durability and high load-bearing capacity during operation.

Chains or rollers

Chains or rollers are the moving parts of the system. They are responsible for pulling products along the hanging rails. Chains are often used in systems that require large loads, while rollers are suitable for light products that require quick movement.

Depending on the specific needs, the system can use a simple chain or a motorized roller to operate.

Product Hanger or Rack

The hanger or rack is where the product is attached during transportation. The hanger is usually a single or double hook, designed to hold the product securely without damaging it during the journey.

Drive Motor

The motor is designed to ensure a stable operating speed and can be adjusted to meet different production needs.

Controller

The controller is the heart of the Overhead Conveyor system, helping to manage and coordinate the entire product transportation process. The controller can be integrated with the overall factory automation systems, helping to monitor the process and optimize operations.

The Overhead Conveyor system consists of 5 main parts

What are the advantages of Overhead Conveyor?

With its flexible and efficient operation, Overhead Conveyor not only helps optimize space but also brings many other benefits to the production process. Below are the outstanding advantages of the hanging conveyor system, helping factories improve productivity and reduce operating costs.

- Saving ground space: Because it is installed high up, this system helps free up ground space for other activities in the factory, while minimizing congestion and increasing space efficiency.

- Reducing labor and operating costs: Overhead Conveyor helps automate the product transportation process, thereby reducing manual intervention and saving labor costs. This also helps increase accuracy and reduce errors in the production process.

- Easy integration: The system can be easily integrated with other automation solutions such as robots, sensors, and control software. This not only improves operational efficiency but also helps factories optimize production and management processes.

- Flexible and continuous conveying capabilities: This system allows for continuous and uninterrupted product conveying, even in work environments with high requirements for speed and precision.

- Enhanced worker safety: Overhead Conveyors also help reduce employee exposure to hot, heavy or harmful products during processes such as coating or processing.

Overhead Conveyor brings many benefits

What are the disadvantages of Overhead Conveyor?

Although Overhead Conveyor brings many benefits, this system is not without its disadvantages that need to be noted. Below are 3 main limitations of overhead conveyors that businesses need to consider before investing.

- High initial investment cost: Installing overhead rails, motors, and related components requires a significant cost, especially for factories with complex requirements for structure and load.

- Complicated maintenance and repair: Although Overhead Conveyor is very durable, when problems arise, maintenance and repair can become difficult and expensive, especially if the components are installed in difficult-to-reach locations. This can affect downtime and disrupt the production process.

- Product Size and Weight Limitations: While Overhead Conveyors can transport a wide range of products, there are limitations to the weight and size of the products they can handle. This can be a factor to consider when selecting a conveyor for very heavy or bulky products.

What are the disadvantages of Overhead Conveyor?

What is the difference between an Overhead Conveyor and a traditional conveyor?

To get a clearer view of the difference between Overhead Conveyor and other types of conveyors, we can compare them through some important factors such as usage area, installation cost, automation integration capability and operating efficiency.

| Overhead Conveyor | Floor Conveyor | |

| Occupying space | Space-saving, airborne transportation | Occupying ground space, limited space |

| Installation cost | High initial investment cost | Average installation cost |

| Ability to integrate automation | Easy to integrate with complex automation systems | Can be integrated but not as flexible as Overhead Conveyor |

| Operating performance | Continuous, high-speed, flexible transportation | Stable transportation, suitable for large products |

| Maintenance | Difficult maintenance due to high installation location | Easy maintenance, easy access to components |

| Application | Suitable for a limited space, highly automated environment | Suitable for large products, direct transportation on the ground |

Where to buy reputable automatic wheel conveyor lines?

If you are uncertain about where to purchase a wheel conveyor, DNC Automation is an excellent option for you. Many customers have trusted DNC to provide automation solutions in the production process and have had positive experiences because:

- DNC is a leading technology, automation, and engineering company in Malaysia with over 15 years of experience in the field of automation

- System integration machinery, Internet of Things (IoT), Industry 4.0, and WinCC Scada System

- Diverse designs and sizes are suitable for many domestic and foreign houses. The equipment is 100% genuine and imported from Malaysia.

Please contact us via the hotline below if you have any questions about the product, we are happy to answer you!

- 0 views

- 0 Comment

Recent Comments